Product DescriptionElectrostatic Discharge (ESD) flooring is also

known as anti-static flooring, comes with anti-static performance

(static-dissipative or conductive), and protects electronics from

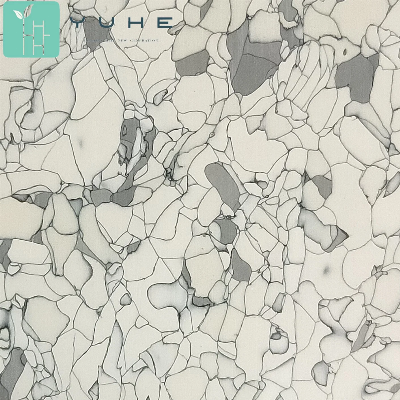

damage caused by static electricity.The ESD flooring tiles are

of high density, non-porous natural organic tile visual.

They're manufactured by an extrusion process, mixing and

pressing the 100% virgin PVC granules with carbon (graphite)

fibers, calcium carbonates, DOPT plasticizer, Titanium dioxide

white paint, etc. under proper pressure and temperature.

Conductive elements are distributed throughout the flooring

material, Thus they give ESD floors electrical conductivity, create

an electrical pathway from the walking surface to the ground, and

guarantee a permanent ESD performance.ESD vinyl flooring tiles are

the choice of professionals for controlling electrostatic discharge

in clean rooms, electronics manufacturing, computer rooms, repair

facilities, or anywhere static-sensitive components are being used

or manufactured.ESD Tile SizesThe popular and standard size is

600×600mm, 610x610mm, 900×900mm.The thickness of the tiles is

mainly 2.0mm, 2.5mm, 3.0mm.Weight: 3980g/m2 (2.0mm

Thickness)Features Low TVOC emissionsMeet

FloorScore®Permanent anti-static propertiesOutstanding abrasion,

scratch, stain, water, chemical, fire, skid, and light

resistanceHigh durability, easy to clean and maintainExcellent

dimension stabilityAntibacterial and fungicidalVarious patterns and

colors Product ParametersTechnical data

ItemStandardDataElectrical

Resistance(Ω)SJ/T11236-2020EN1081Conductive Dissipative 1.0x

10E4 - 1.0 x 10E6 ohms1.0 x 10E6 to 1.0 x 10E9 ohmsDimensional

Stability(%)ASTM F2199:09(2014)ISO 23999-20180.05%Starting

VoltageSJ/T 10694-2006EN 1815IVI < 100V< 2KVAATCC-13450 V100

VStatic Decay(s)GJB3007A-2009≤ 2 secFederal Test Method1018 Method

40460.01 sec0.01 secWear Resistance(1000r)EN 660-2Class

PSJ/T11236-2020≤ 0.020 g/cm2Fire

ResistanceSJ/T11236-2020FV-0GB8624-2012B1(B-s1, t0)ASTM

E648-17Class IEN13501-1Bfl - s1Slip Resistance WetDIN

51130R9Residual Indentation(mm)GB/T4085-2015≤ 0.15 ≤ IR ≤ 0.40mmISO

24343-1:20120.03mmColor FastnessISO 105-B02≥ 6Chemical Products

ResistanceEN ISO 26987: 2012OKToxic TestingGB 18586-2001EN

71-3OKTVOC After 28 Days(μg/m³)ISO 16000-3< 10 μg/m³

Our Advantages1. Advanced ManufacturingFull-automated production

lines to ensure higher production capacity and efficiency.The

longest-tempering production lines in China to control

dimensional stability effectively. 2. Good-quality

environmental-friendly raw material We use DOTP plasticizer for ESD

PVC flooring.Dioctyl terephthalate commonly abbreviated DOTP or

DEHT. It is a non-phthalate plasticizer that is considered safer

than ortho-phthalate plasticizers due to its excellent

toxicological profile.The product does not contain carcinogens such

as benzene and heavy metals such as lead. And it's of low TVOC

emission. 3. R & D StrengthPatents in production process

optimization.We have an independent testing laboratory with

appropriate testing instruments and equipment.Testing and

calibration are performed using USA/EU/JAPAN/CHINA standard

methods. So we can produce ESD vinyl flooring products in

compliance with different standards. We have TVOC, RoHS, and

SGS certificates contributing to good indoor air quality

(IAQ) for durable and sustainable static vinyl flooring

tiles. We implement a pretty good color and size management

solution. Wear resistance reaches P class in all ESD vinyl

flooring series. We're proud to complete vinyl flooring

projects for Flex, BOE, Huawei, Foxconn, Samsung, Gree, Mindray,

etc. in China. Packaging &

Shipping Certifications /*

January 22, 2024 19:08:37 */!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about ESD Static Dissipative PVC Flooring Tiles

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup