ModelCore material Core material DensitySkin materialSkin

thickness(mm)Total Thickness(mm)Standard size

(mm)FRPx-PP8T40F-xxPP8T40F85 KGS/M3FiberglassX:

0.5/1.0xx:10-601200*1200FRPx-PP8T40F-xxPP8T40F85 KGS/M3FiberglassX:

1.5/2.0xx:10-601200*2400CRPx-PP8T40F-xxPP8T40F85 KGS/M3Carbon

fiberX: 0.4/0.6xx:5-301200*1200ALUx-PP8T40F-xxPP8T40F85

KGS/M3AluminumX: 0.6/1xx:10-401200*1200PLYx-PP8T40F-xxPP8T40F85

KGS/M3PlywoodX: 3/4xx:15-601200*2400Other skin material, thickness

and different core density can be made for scale order,

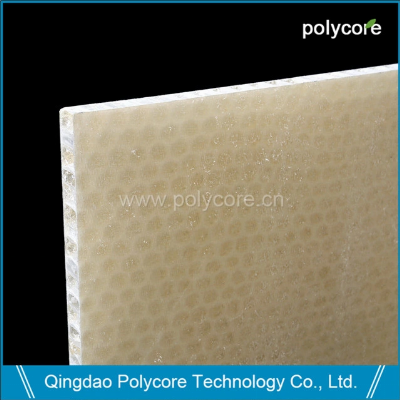

negotiation.FRP PP honeycomb sandwich panel- Original SkinFRP PP

honeycomb sandwich panel- anti-slip SkinFRP PP honeycomb sandwich

panel- add Melamine SkinFRP PP honeycomb sandwich panel-

fire-retardant Skin Product Description Polycore

Technology is a leading manufacturer of honeycomb and lightweight

composite solutions. Honeycomb cores are used in the fabrication of

lightweight structures.The core material is typically 'sandwiched'

between skins of Fiberglass materials.Fiberglass pre-immerged resin

sheet (FRP ) as skin panel on both sides, PP honeycomb as core.

They are composited from high pressure and heating. The features of

our FRP PP honeycomb sandwich panels are light weight,high

stiffness, sound damping,fire-retardant, quakeproof,insulation,

environmental friendly.FRP surface thickness from 0.3mm to 3mm made

according to clients request.UV-treatment, Anti-slip, Sanding

surface,Gel-coat treatment, Painting treatmentand so on can be made

according to clients request.Standard specification: 1200*2400mmMax

specification: 2500*12000mm Product Application Polycore

Technology FRP PP Honeycomb Sandwich Panel ApplicationsThey are

applicable to the apartments and external walls of building Truck

body, widely Used in boat, Yatch, wind turbine, sports, tank cover

and so on.FRP PP honeycomb Sandwich board is widely applied in

Marine as structural material such as hull, deck, bulkhead, tank,

canopies and cases; In Tooling as fabricating tooling and moulds;In

truck as truckWall, Fairing, Ceilingand floor hoods;In wind turbine

act asblades, canopy housing and rotor hoods; In sport as leisure,

film set and decorative market;In corrosion to prevent and repair

of metal and concrete surfaces;In chemical barrier to provide

protection for tanks, pits, pipesand grates.In above applications,

honeycomb sandwich panel can cut down body weight, increase speed,

save energy, whilst providing strengthlessen shakiness.

Company Profile Qingdao Polycore Technology Co.,ltd is a

leading manufacturer of materials used for building, cooling,

decoration, transportation, Electron, air purify.The main products

range include the following:PP honeycomb for air purifier,

transportation as wall ,ceiling, floor for van, boat, yatch,

construction, etc, applicationPC honeycomb core for commercial

refrigeration, laser cutting, decoration, applications. FRP PP

honeycomb composite board for sports, transportation, building,

etc.PC honeycomb composite board for partition, decoration,

etc.Night cover for commercial refrigeration. Hard tube for

electrical, decoration, lighting, plant ,etc, application.Qingdao

Polycore commits to provide consistent quality products with

services to market. We would like to be your reliable long-term

business partners. FAQ Q. Why use a FRP PP honeycomb

sandwich panel?A. PP represents Polypropylene, FRP represents

fiberglass, honeycomb structural is known for its high strength,

light weight. FRP PP honeycomb sandwich panel applied into project

can cut down weight, improve speed, keep strength, reduce

energy consumption in transportation, It also damping

sound and vibration. FRP PP honeycomb sandwich panel speed up

project process, dampen sound pollution, save energy cost in many

other applications.Q. What do you think about the performance of

FRP PP honeycomb sandwich panel?A. FRP PP honeycomb sandwich panel

work perfect till to now. It is eco-friendly and it can be reused

and repaired if there is damaged in partly.Q. Is FRP PP honeycomb

sandwich panel waterproof?A. PP honeycomb panel is moisture and

corrosion resistant. It is absolutely lightweight. It is also

resistant to chemicals. The thickness will range from 10mm to 80mm.

Q. How about FRP PP honeycomb Sandwich panel working temperature?A.

PP honeycomb core can keep its shape under working temperature

-20--- 80 Celsius degree. So FRP PP honeycomb sandwich panel

suggest working on same temperature range.Q. Is FRP PP honeycomb

sandwich panel fire resistant?A. PP honeycomb panel is flammable.

Original FRP PP honeycomb sandwich panel is fire-retardant in some

extent. But if need more better fire-retardant grade, we suggest

Fire-retardant FRP skin on PP honeycomb and seal all edges of

sandwich panel with fire-retardant material.Q. Can we ask a free

sample?A. Original FRP PP honeycomb panel sample is freely provided

,usually dimension within 200*200mm, you just need to pay express

freight from our address to you. /* January 22, 2024

19:08:37 */!

Related products about Waterproof Light Weight High Strength Honeycomb Sandwich Panel

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup