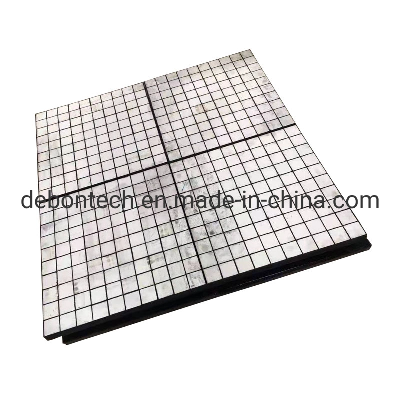

Hex composite ceramic rubber linerOur Service:1. Rich experience on

production process of ceramic rubber wear liners2. Strict quality

control on ceramic liners3. Good delivery time4. Custom shape

ceramic wear liners are available.5. Excellent bonding between

rubber and ceramicDescription:Rubber ceramic wear liner, rubber

backed ceramic tile mat is embedding high alumina ceramic into

energy absorbing rubber or polyurethane cushion, and bond both to

steel backing plate via hot vulcanizing for easy

installation.Energy-absorbing rubber cushions helps reduce

impact energy and prevent ceramic tiles breakage,Steel backing

plate with studs for easy installation.Features:High alumina

ceramic wear tile offers high abrasion resistance, acid and alkli

resistance is effectively prolong the service life of equipment and

considered to be the best choice of anti-wearing and anti-corrosion

material; Wear resistance of alumina ceramic is 200 times than that

of special manganese, 170 times to high chrome cast iron; Hardness

is much higher than that of wear-resistant steel and stainless

steel.Application:The wear resistant ceramic rubber chute liners

are widely used for serious abrasive environments, such

as chute liners, cyclone liners, conveyor skirt liners, processing

piping liners, hopper or silo liners, screen equipment liners in

the industries including ,but not limited to: ♦ Coal

Preparation

Plants ♦

Coal Fired Power Stations♦ Mineral Processing

Plants ♦ Cement

Plants♦ Chemical

Plants ♦ Steel

& Iron Plants♦ Railway

Stations ♦ Ports

Technical information:1) Alumina tiles: al2o3 92% or 95%2) Density:

3.64g/cm33) Compressive strength: above 2,000MPa4) Water

absorption:

Related products about Composite Bin Liner Aluminum Ceramic Rubber Sheet

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup