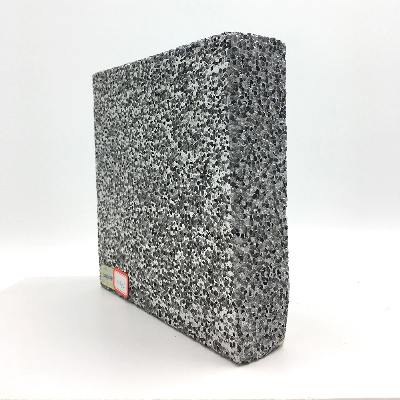

Product DescriptionClosed cell aluminum foam panel for

fireproofAluminum foam sheet is a type of aluminum sheet with a

porous structure, also known as aluminum foam or aluminum foam

material. It is usually made from pure aluminum or aluminum alloy

through a mixture of aluminum powder, foaming agent and other

additives.The process of making aluminum foam panels usually

includes the following steps: first, aluminum powder is mixed with

blowing agents, thickeners and other additives to form the raw

material of aluminum foam material. Then, the mixture is injected

into a mold and foamed and cured at a certain temperature and

pressure to form a solid structure of the aluminum foam material.

Finally, the final aluminum foam sheet product is formed through

processes such as cutting, trimming and surface treatment.Product

ParametersBasic FeatureChemical compositionOver 97% AluminumCell

typeClosed CellDensity0.3-0.75g/cm3Acoustic FeatureAcoustic

absorption CoefficientNRC0.70-0.75Mechanical FeatureTensile

strength1.3-2.0 MpaCompressive strength1.5-2.0 MpaThermal

FeatureThermal conductivity0.268W/m.KMelting pointApprox.780ºCExtra

FeatureElectromagnetic waves shielding abilityOver90 dbSalt spray

testNo CorrosionProduct Feature1. Lightweight: Aluminum foam sheet

is a lightweight material, much lighter than solid aluminum sheet

due to its porous structure and relatively low density. This gives

it an advantage in applications where weight reduction is required,

such as aerospace and transportation.2. High Strength: Despite its

lower density, the pores in the structure of aluminum foam panels

are evenly distributed, creating a strong network structure. This

gives aluminum foam panels high strength and rigidity, with some

resistance to compression and bending.3. Good energy-absorbing

properties: Due to the existence of porous structure, aluminum foam

panel has excellent energy-absorbing properties. When subjected to

impact or extrusion, its pores can absorb and disperse energy,

playing the role of buffer and protection, so that it is used in

the field of collision protection, military protection and so on.4.

Good thermal and acoustic insulation: the porous structure of

aluminum foam panel has good thermal and acoustic insulation

properties. It can reduce heat conduction and sound transmission,

which is suitable for building insulation, sound control and other

applications.5. Corrosion resistance: Aluminum foam panel is often

made of pure aluminum or aluminum alloy with good corrosion

resistance, which has excellent corrosion resistance. It can resist

oxidation, corrosion and some chemical substances, suitable for

some applications in harsh environments.6. High processability:

aluminum foam sheet can be processed by conventional metal

processing methods such as cutting, drilling and welding. It can be

customized in shape and size according to specific needs, adapting

to various application scenarios.ApplicationIt can be used in the

following places to control reverberation time effectively:

libraries, meeting-rooms, theatres, studios, KTV, stadiums,

natatoriums, subway stations, waiting rooms, hotels and

restaurants, shopping malls, show rooms, wireless houses, computer

houses and so on.Packaging & ShippingCompany Profile /*

January 22, 2024 19:08:37 */!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Closed Cell Foam Aluminum Panel for Fireproof

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup