Our advantages / Why us ?A, Help to Save your

money / budget by Manufacturing aluminum honeycomb

core, honeycomb panel, solid aluminum sheet,stone honeycomb panel,

porcelain honeycomb panel inhouse, have our

own export right to do all deals, no need any trader in

between; B, You will get the full solution of

panel & Fixing system, shop drawings with our experienced

engineers & production team because we focus on various

honeycomb panels engineering & production since 1994; C,

Save a lot transportation fee, labor cost, job site work

hours of installation as the honeycomb panel is 3

times lighter than the traditional solid panel; D,

Ultra-lightweight, High Rigid, and fire-rated make

your buildings reduce a lot of weight, increase the

durable and safe; E, We supply One Stop service, to help

you save a lot of your time and money. Applications

/ Apply to

:a). Building exterior curtain walls; internal

curtain walls; canopy; b). Marine partition,

ceiling,deck, furniture, ship hull

decoration; c). Toilet partition; d).

Decoration and renovation additions for old buildings; e). Decoration of interior walls, partition,

ceilings, bathrooms, kitchens and balconies; f).

Shop door decorations; g).

Advertisement board display platforms and signboards; h).

Wallboards and ceilings for tunnels;i).

Industrial materials, materials for truck

body, vehicles and boats. j). Cleanroom

partition, ceiling and wall cladding. Product

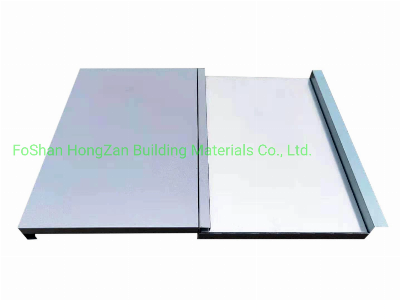

Parameters What is Aluminum Honeycomb Panel ? Aluminum

honeycomb panel are mainly used for the decoration of ship and

building.1), made of high-quality imported raw materials, and

processed with high precision.2), Its surface employs

fluorocarbon lacquer( PVDF, PE) pre-roll coating of which can

keep the color unchanged for 15-20 years.3), Adopted and

bi-component modified epoxy adhesive and has used fully automatic

manufacturing facilities of honeycomb panels to

compound product under pressurized high temperature through

completely-closed and dust-free operation, which make the honeycomb

panels sticker, more bending resistant, straighter, and thus

steadier and more reliable in quality.4), All kinds of

alloyed honeycomb panel, such as single curved panels, double

curved panels, folded panels and trapezoidal panels, can be

fabricated according to the requirements of architectural

design.5), The alloyed panels with non-planar surfaces, such

as circular arc, L type and U type, are produced by one-step

forming with dies. It is a kind of organic and environmentally

protective decorating material with high quality, light, high

strength and magnificent appearance. HZ Honeycomb aluminum

panel is one of the best environmental composite materials

with perfect strength, super flatness and excellent sound

& heat insulation but with ultra-light weight and easy

installing. The panels can be manufactured based on your

specifications for a various

applications. Structure of Aluminum Honeycomb

Panel:Product Description Main features: A. Ultra-Light

weight, high rigidity, steady, structure and high wind-resistance

performance.Curtain wall aluminum honeycomb panels have been

extensively applied to external wall decoration of high-rises

building.Honeycomb panels of the same rigidity have a weight that

is only 1/5 of aluminum panels and 1/10 iron panels, whose total

thickness being 15mm, panels 1.0mm thick and bottom panel 0.8mm

thick have a weight of only 6kgs per square meter. The

interconnected honeycomb cores are like numerous I bar with

interface layers distributed within the whole panel, thus resisting

shearing and bending and large pressure. Its wind-resistance

performance has greatly exceeded that of aluminum composite panel

and aluminum solid panel, so that even large- sized honeycomb

panels can reach extremely high straightness, aluminum honeycomb

panels can reach the highest highest intensity and bending

resistance with the lightest weight, which is an incomparable

compared to other materials, thus making it currently the preferred

light weight material in the building industry.B. Excellent

performance in sound insulation, heat insulation, reproofing and

quake proof.Since the honeycomb cores in aluminum honeycomb panels

are divided into many enclosed cells, which stops air flows and

blocks heat and sound waves with 20-30DB, noise reduction for

sources from 100HZ to 3200HZ and a heat conduction coefficient of

0.104-0.130W/M.k, Aluminum honeycomb panels is an ideal

energy-saving material with an energy absorption capability of

150~3500KJ/M. For example, when it is raining, rains dropping on

the aluminum solid panels or aluminum composite panels will make a

loud noise, but if replaced them with honeycomb panels, no such

problem will happen. C. Straight surface, colors

variety, super smooth. Aluminum honeycomb panel has high

flatness, and has the advantages of easy deformation, slab roller

coating aluminum with fluorocarbon. PVDF coating aluminum roll the

most important point is that with a continuo

Related products about Sandwich Panel Aluminum Sheet Honeycomb Composite Panel Building Material

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup