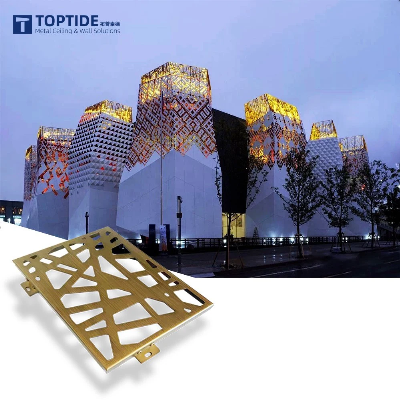

laser cutting metal carved cladding panel aluminum perforated

curtain wall board Services 1, Free small samples;2,

Provide design proposal;3, Strict inspection process;4, Supply

warranty certification. Product Description1. Perforated

aluminum cladding panels are a type of exterior wall cladding

system that is made from aluminum sheets that have been perforated

with a series of holes or patterns. The perforations can be

designed in a variety of shapes and sizes, and can be customized to

suit the specific requirements of a building's

design.2. Perforated aluminum cladding panels are commonly

used in architectural applications, such as facades, sunshades, and

privacy screens, as well as in industrial and transportation

applications, such as ventilation systems and noise barriers. They

offer a range of benefits, including improved energy efficiency,

enhanced aesthetic appeal, and increased functionality.3. One

of the main advantages of perforated aluminum cladding panels is

their ability to provide improved ventilation and airflow. The

perforations allow air to circulate freely through the panels,

which can help to reduce the temperature and improve the comfort

level of a building or structure. Additionally, the perforations

can help to reduce noise levels by absorbing sound waves, making

them ideal for use in noisy environments or high-traffic

areas.4. Another advantage of perforated aluminum cladding

panels is their aesthetic appeal and design flexibility. The

perforations can be customized to create a range of patterns and

designs, from simple geometric shapes to intricate patterns and

images. The panels can also be finished in a range of colors and

textures, including metallic finishes and wood grain patterns, to

suit the design preferences of the building.5. Perforated

aluminum cladding panels are also highly durable and low

maintenance. Aluminum is a lightweight material that is resistant

to corrosion and weathering, making it ideal for use in harsh

environments or high-traffic areas. The panels can be easily

cleaned with a damp cloth or mild detergent, reducing maintenance

costs and ensuring a long service life.6. Overall, perforated

aluminum cladding panels offer a versatile and attractive solution

for exterior wall cladding, providing both aesthetic and practical

benefits for designers and builders. The perforations can be

customized to suit a range of design requirements, while the

durability and low maintenance properties of the material make it a

popular choice for a variety of architectural

applications. Product NameCustomized Perforated

AluminumCeiling PanelMaterialsAluminum AlloyGalvanized

SteelThickness1.2mm, 1.5mm, 2.5mm, 3.0mm, 4.0mm0.8mm, 1.0mm, 1.2mm,

1.5mmWidth300-1500mm300-1000mmLength≤4000mm≤2400mmSurface

TreatmentRoller Coating, Powder Coating, PE/PVDF, Heat Transfer

Printing, Interior Film, Wood Veneer, Polyester Baking Finish,

Aluminum AnodizingShapeVariety of shapes ApplicationAirport,

metro, railway station, business center, gymnasium, bank, hotel and

etc. PackagingCarton Package Product PicturesNormal

Perforations

Various puching shape and designs as below for choice, and customized perforations & carvings are available too.(Due to different ceiling tile thickness, some perforations may not workable.)Features

1. Acid and alkali and other harsh environment, can ensure the

stability of the material;2. After fastening carriers, workmen can

easily install ceiling tiles by hand;3. Convenient installation,

unconventional appearance, revealing elegance;4. Suitable for large

open areas with durable and clean look;5.Various standard and wide

choice perforations;6. Good protection to building structure;7.

Convenient installation, unconventional appearance, revealing

elegance;8. Outstanding performance with high quality products;9.

Anti-pollution, easy to clean; Installation

Instructions ColorsVarious colors and shadows as below for choice, and customized colors are available too.(Due to printing limitation,

color may vary from actual product.)Project

Cases Factory Profile Factory is covering an area

of 50,000 square meters around, yearly capacity: Non-standard

products are above 1 million square meters an standard products are

above 2 million square meters. We have high-end machine in the

world, like Italian SALVAGNINI P4X Metal Sheet Processing

Equipment, Canadian IKE 7.5-Meter Numerical Control Bending Machine

and British YILUDA Automatic Painting Line. With 75% high rate of

production automation, we'll meet customized

requirements.Machinedis playThe world 's most sophisticated

Savannini , ItalyMultilateral CNC bending equipment Lean

Production.P4X system is the perfect solution for lean production

equipment, simplify the production process, minimize waste and

eliminate labor cost .The unmanned operating system can fully

automatically produce , maximize the production efficiency .Each

workpiece processing only needs18'-25' to complete. CNC

material perforated equipmentJapan A

Related products about Laser Cutting Metal Carved Cladding Panel Aluminum Perforated Curtain Wall Board

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup