-----------------------------------------------------------------------------------Production

processes----------------------------------------Import Raw Wood We

can guarantee the quality of raw materials. All of our raw wood

materials are sourced from high-quality forest production areas at

home and abroad, such as Australia, New Zealand, Brazil, and

domestic high-quality forest production areas. We will not easily

raise the price of products because of the fluctuation of raw

materials.Automatic log peeling processAfter each log is selected

by the saw head and edged, the bark is peeled off by the machine.

The peeling is divided into veneer peeling and core board peeling.

Each plywood core board is made of eucalyptus or pine wood, while

the veneer is made of pine wood to ensure that each board does not

warp, deform, crack, have good water resistance, high turnover

rate, and repeated use times.Veneer Sun Drying Artificial

professional drying board, drying each wet veneer after peeling in

the sun, strictly controlling the dry humidity of the board, and

the moisture content of the veneer is 20-50 lower than the market.

Refined management system The company follows the leading

level of quality indicators, so that quality control covers and

runs through the entire process of the company's production and

operation. With the most professional attitude, continuously

improve the level of fine processing management, ensure that each

link is carried out under the fine and precise operating standards,

and form a reasonable structure, strict procedure, and effective

operation management mechanism.Strictly inspect the quality The

company adheres to the value of "responsible to the enterprise,

responsible to the user, and responsible to the society", strictly

implements a scientific and reasonable quality inspection process,

conducts a full range of inspections on each template, and ensures

the high quality of each template with a high sense of

responsibility Won the recognition of the

society.-----------------------------------------------------------------------------------Factory

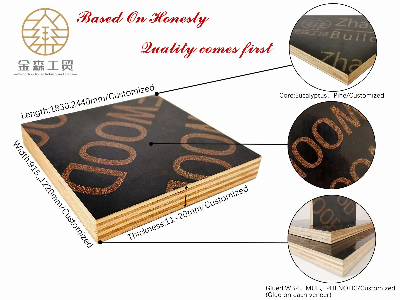

scene------------------------------------------------------------------------------------------------------------------------------------About Product------------------------------------------------Phenolic

glue/Phenolic film facedrolling in the board of the outermost

layer,waterproofMelamine gluehas three colors,black and white

red,used in different thickness of theveneer,to prevent typesetting

workers take the wrong plate to distinguish.Waterproof Glueyellow

and red,according to customer requirements to spray,for the board

border water role.Product specificationsProduct Name:Film faced

plywoodSpecification:1830*915/1830*1220/2440*1220Thickness:12,13,14,15,17,18,20,21,24mm/CustomizableCore:Pine,Combi,EucalyptusMoisture:8%-12%Film:Black,Brown,Red,Pastic

FilmGlue:MR,WBP-Melamine,WBP-PhenolicUsage:For outdoor

construction/concrete formwork/shuttering workGrade:A+:Plastic

faced plywoodA:Two time hot pressingB:One time hot pressingC:Finger

Joint Package:Carton package/Plywood package for

export.Loading Quantity:(1220*2440mm)20GP8Pallets40HQ18PalletsPrice

Term:FOB,CNF,CIF,etc.Delivery time:Within 15 days after receiving

deposit.-----------------------------------------------------------------------------------About Company----------------------------------------------

Zhangzhou Jinsen Industry and

Trade Co., Ltd. is located in Zhangzhou City in the Golden Triangle

Area of Southern Fujian, adjacent to the Xiamen Special Economic

Zone. It has developed transportation advantages such as highways,

inland rivers and ocean shipping, and unique geographical

advantages. The company's predecessor was Jiasheng Wood Processing

Plant, which was established in 2004. Due to the company's

development needs, it is now renamed "Zhangzhou Jinsen Industry and

Trade Co., Ltd.". The company has four brands: Changqiao,

Songchang, Shangchuan and Wanxing. Its main product specifications

are 183*915, 183*122, 122*244mm and other high-level building

templates of various thicknesses.

Although with the rapid development of science and

technology, for more than ten years, the company has been

continuously forging ahead, researching and innovating, achieving

standardization, enterpriseization, and a modern scale enterprise

that can independently innovate and research. The company continues

to introduce advanced production equipment at home and abroad to

connect domestic and foreign timber to finished product R&D and

production. It can independently complete a complete set of

processes from raw materials to product design and then finished

product production, and vigorously expand domestic and foreign

markets. Relying on the concept of "honesty, quality first", with

its excellent quality and perfect after-sales service, the company

has become the leading brand of wooden plywood in the industry that

is widely welcomed by customers at home and abroad.

Related products about Best Quality E1 Melamine Black Coloured Laminated Plywood Sheet for Pallet Marine Plywood Film Faced Plywood

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup