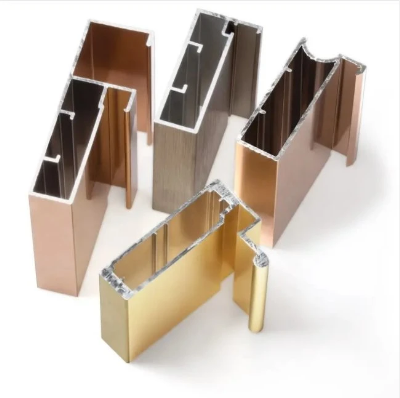

Product Description ItemAluminum Window Door ProfileAvailable

MaterialsAluminum 6063FinishPowder coating, Anodizing(Oxidation),

Sandblasting, Brushing, Painting, Passivation, Silk screen,

Polishing, Galvanise,(Nickel/Tin/Chrome/Copper) Plating,

etc.Payment TermsT/T : 30% before hand, balanced 70% before

shipping;Industry FocusAppliance/ Automotive/

Agricultural/Electronics/ Industrial/ Marine/Mining/ Hydraulics/

Valves/Oil and Gas/ Electrical/ Construction/ machinery/furniture/

toy/ woodboard/ wall/ agriculturalIntended ApplicationsAuto

parts; Household Electric Appliances; Medical

equipments; Fitness equipments; Electrical

machinery; 3D printer; Computer case; Desktop

computer; Electrial Cabinet/box; Electronic

product;Network chassis; Servers rack; Medicine

cabinet;Industrial manipulative computer; Machine enclosure and

Frame;Tool Cabinet and chest; Mountain /wall

bracket;Tolerance+ 0.1mmSection sizeSquare: ≤ 150*150mm

Rectangle:≤ 250*50mmRound: ≤ ∅170mmPackageInner

plastic paper/PE paper interleaving each piece;Outer fixed by

plywood or pallets with shipping mark;Or as required.Lead

TimeSample: within 10 days.Mass Production: within 10-25 days after

receiving the depositRush Services Available Product

Parameters1) Chemical

compositionAlloySiFeCuMnMgCrZnTiImpurityAl60630.2-0.60.350.10.10.45-0.90.10.10.10.15Rest60610.4-0.80.70.15-0.40.150.8-1.20.04-0.350.250.150.15Rest60600.3-0.60.1-0.30.10.10.35-0.6-0.150.10.15Rest60050.6-0.90.350.10.10.40-0.60.10.10.10.15Rest 2)

Mechanical propertyAlloyTemperTensile strengthYield

strengthElongation6063T5≥ 160Mpa≥ 110Mpa≥ 8%T6≥ 205Mpa≥ 180Mpa≥

8%6061T6≥ 265Mpa≥ 245Mpa≥ 8% Technical Support 1. Based

on the customer's requirements, we help design the appearance of

the extruded profiles, provide CAD drawings and 3D models for

customer confirmation, customize the molds, and extrude the

aluminum profiles that meet the customer's requirements.2. For

customers with design capabilities, our professional R&D team

will analyze and optimize the design based on the customer's

drawings and our experience in extrusion processing, using the most

reasonable design to reduce production costs and improve product

performance.3. Our company adopts a "one-stop" service and

production model, including product design, customized molds,

aluminum bar melting and casting, extrusion profiling, precision

machining, and surface treatment. We can effectively control the

alloy composition of raw materials and maintain product accuracy

throughout the production process, providing you with high-quality

products.Factory EquipmentExtrusionEquipped with 44 aluminum

extrusion lines, MetalPlus is capable of producing

various standards of commercial aluminum profiles and industrial

aluminum profiles with maximum outer diameter of

350mm.MetalPlus has 44 aluminum profile extrusion lines

equipped with PLC control systems and precise molds. The largest

extruder used in the MetalPlus factory is

a 6800 ton unit. The machine is used for the production

of industrial profiles in various shapes with a maximum diameter

of 600mm. This allows us to satisfy the different requirements

of our various customers. Some of the aluminum products produced

by MetalPlus include radiators, industrial fan blades,

motor enclosures, solar cell frames, doors, and

windows.MetalPlus can produce custom molds according to

customer requirements. We have the abilities and experience to

produce aluminum profiles with complex structures. We have our own

R&D team so we can provide reasonable suggestions for our

customers in order to create superior products at affordable

prices. AnodizingAnodizing is a process in which a layer of

aluminum oxide is formed on the surface of aluminum alloy products

when they are placed in an electrolyte solution and then an

electrical current is applied. Oxidized aluminum profiles feature

improved corrosion resistance so that the surface can withstand

various weather conditions. Meanwhile, the aluminum oxide also

increases the product's hardness and wear

resistance. MetalPlushas 6 anodizing production lines. The

profiles processed in our anodizing lines feature uniform oxidation

film thickness and color giving them a beautiful appearance. The

oxidized profiles come in various color options including silver,

black, gold, champagne, and imitation steel. Other colors can be

customized upon request.The anodized products will all be inspected

by highly trained professional inspectors. Defective products which

cannot be re-processed will be directly scrapped. Products with

uneven color will be de-coated and re-anodized until they can meet

the requirements. This ensures that there is no color difference

among each batch of products.PaintingOur factory is equipped with 4

powder spraying lines and all of them are using high-quality spray

nozzles from Gema Switzerland. In the

meantime, MetalPlus only uses safe and environmental

friendly paint with strong adhesive force as well as durable color

retention.CNC MachiningMetal

Related products about Fluorocarbon Coating PVDF Aluminum Window Door Extrusion Profile

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup