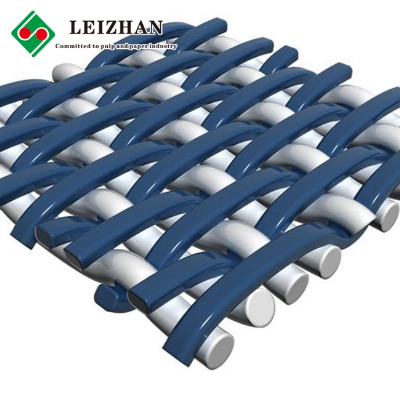

Product DescriptionPolyester Forming Fabric is used

paper-making on a paper machine so it is also called paper

machine clothing or paper making fabric. Polyester forming

fabric can be divided into 4-shed, 5-shed, 8-shed,

16-shed, 20-shed and 24-shed according to the

weaving type, etc. It can also be divided into

single layer fabric, double layer fabric, two-and-a half layer

fabric and three-layer fabric according to the category.4-shed ,

5-shed series single layer polyester forming fabrics are the two

widely used polyester forming fabric in paper making, mainly used

for producing cultural paper (single glue, double glue and color

glue), printing paper, glazed paper, packing paper, common

newsprint. Suitable for common fourdrinier paper machine.8-shed

single layer polyester forming fabric is suitable for kraft paper,

cardboard , corrugated paper making. Also could be used for

producing common printing paper. Suitable for common fourdrinier

paper machine.8-shed double layer fabric is suitable for producing

quality printing paper. For example ,dictionary paper, offset

printing paper, newsprint and wrap paper. It can be used for tissue

paper making and the surface pulp, lining pulp, core pulp and

bottom pulp of the board paper etc. Suitable for medium and high

speed paper making machine.16-shed double and a half layer

polyester forming fabric is suitable for producing quality printing

paper, such as offset printing paper, copper plate paper, newsprint

and cigarette paper series (wrap paper and filter tips paper), Also

is could be used for producing toilet paper, tissue paper and

surface pulp, lining pulp, core pulp and bottom pulp of the board

paper etc. Suitable for medium and high speed paper making

machine.Multi-shed three-layer fabric is suitable for producing

quality printing paper, tissue paper and cigarette paper etc.

Suitable for high speed paper making machine. Product

ParametersParameter of single and 1.5 layer is as following:Single

& 1.5 layer paper making forming wireWeaving series & typesFabric

ModelWire Diameter mmDensity(root/cm)Tensile strengthTicknessmmAir

PermeabilityM3/m2hForce elongation(in 50N/cm Tension,Tension rate

not more than)WarpWeftWarpWeftSurfaceJoint4-shed single layer

forming

fabricSFW272540.200.252922≥600≥4000.497500±5000.60%SFW272740.200.273022.5≥600≥4000.517600±5000.60%SFW312540.200.223528≥600≥3800.436500±5000.68%5-shed

single layer forming

fabricSFW272150.200.253023≥600≥3500.57600±5000.60%SFW272850.220.283023≥600≥5000.487800±5000.60%SFW312050.200.213532≥600≥4000.486700±5000.60%8-shed

1.5 layer forming

fabricSFW253580.220.352819.5≥700≥5000.869000±5000.65%SFW254580.220.3829.519≥700≥5000.888500±5000.65%SFW273580.220.352920≥700≥5000.868500±5000.65%SFW274080.220.4031.519≥700≥5000.888000±5000.65%For

2.5 layer and forming wire parameters, please

visit:https://leizhan.en.made-in-china.com/product/jOHQbPvYnThW/China-1-5-Layer-Paper-Machine-Forming-Wire.htmlFor

3(triple) layer parameter, please

click: https://leizhan.en.made-in-china.com/product/KSlxkodTANYU/China-Triple-Ssb-Layer-Forming-Fabric-for-Paper-Machine.html

Detailed Photos Installation Instructions1. Before installing

the forming wire, kindly check the equipment if it is in good

condition, the surface of wires should be forbidden from

unevenness, slanting, burr, sand, etc.2. The running direction must

be in accordance with the direction of the arrow on the wire, the

wire should be placed in the correct position, and the rollers

should be paralleled with each other to prevent the wires from

being deflected.3. There should be a swinging high-pressure water

device that used to wash wire. Water pressure is not lower than

6-10 kg/cm² for the medium and low-speed paper machine; speed more

than 350m/min, water pressure is not lower than 10-15 kg/cm²; When

using multi-layer forming wire, water pressure is not lower than

15-30 kg/cm², meanwhile water should be clean and without sand.4.

When installing the forming wire, firstly let the wire be slightly

tensioned, add water to lubricate the operation, adjust the tension

to normal after sizing, keep the tension of the low-speed paper

machine at 3-4 kg/cm², and high speed one at 4-6 kg/cm². Our

AdvantagesRelated ProductsPaper Machine

Felt: https://leizhan.en.made-in-china.com/product/eZgAGTCUqQkm/China-Paper-Mill-Press-Felt-Pick-up-Felt-Double-Layer-Pick-up-Felt-for-Paper-Machine.htmlRound

Yarn Dryer

Screen: https://leizhan.en.made-in-china.com/product/uNZTtwVDkdfK/China-High-Quality-Polyester-Filter-Belt-Net-Screen-Round-Wire-Yarn-Dryer-Fabric-Mesh-for-Paper-Making-Machine.htmlSpiral

Type Dryer

Screen: https://leizhan.en.made-in-china.com/product/EdhtQrpyuncA/China-Good-Quality-and-Best-Price-Paper-Pulp-Mill-Spiral-Polyester-Dryer-Weave-Mesh-Fabric.htmlFlat

Yarn Dryer

Screen: https://leizhan.en.made-in-china.com/product/IOEThrUPIQRM/China-Polyester-Flat-Yarn-Dryer-Fabric-for-Paper-Mill.htmlThank

you for browsing, if you have any needs, please feel free to

contact us at any time, wis

Related products about 100% Polyester Dryer Screen Fabric Wire Cloth for Paper Mills

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup