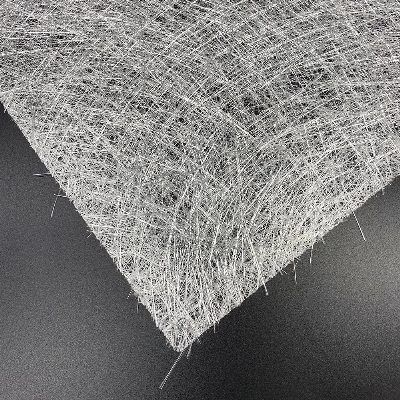

Product DescriptionFiberglass Chopped Strand MatEmulsion binder &

Powder Fiberglass chopped strand mat consisting of randomly

Distributed chopped strands held together with an emulsion binder &

Powder binder. Product Feature1)Uniform density ensures consistent

fiberglass content and mechanical properties of the composites

products.2)The mats features good mat integrity, good unwinding,

easy cutting, little loose fibers and no flying fibers during

handling...3) Excellent flexibility ensures good mold ability with

no spring back at sharp angles.4) Fast and consistent wet-out speed

in resins and rapid air lease enhance molding productivity and

mechanical properties of the end products Product

Parameters Spec. (g/sqm)Width (mm)Area Weight(g/m

2

)Moisture ContentCombustible Content (%)Powder (EP)Emulsion (EE)CSM100g/m

2(50~3120)±5100±10%≤0.20%8.0-9.87.5-8.0CSM120g/m

2(50~3120)±5120±10%≤0.20%8.0-9.87.5-8.0CSM200g/m

2(50~3120)±5200±10%≤0.20%3.6-4.54.5-5.5CSM225g/m

2(50~3120)±5225±10%≤0.20%3.0-5.03.0-5.0CSM300g/m

2(50~3120)±5300±10%≤0.20%3.0-5.03.0-5.0CSM375g/m

2(50~3120)±5375±10%≤0.20%3.0-5.03.0-5.0CSM450g/m

2(50~3120)±5450±10%≤0.20%3.0-5.03.0-5.0CSM600g/m

2(50~3120)±5600±10%≤0.20%3.0-5.03.0-5.0CSM900g/m

2(50~3120)±5900±10%≤0.20%3.0-5.03.0-5.0ApplicationIts end-use

applications include boats, bath equipment, automotive parts,

chemical corrosion resistant pipes, tanks, cooling towers and

building components.Packaging & ShippingShipping &

StorageUnless otherwise specified, Chopped Strand Mat should be

stored in a dry, cool and rain-proof area. It is recommended that

the room temperature and humidity should be always maintained at

15ºC~35ºC and 35%~65% respectively.PackagingEach Chopped Strand Mat

is wound onto a paper tube which has an inside diameter of 76mm and

the mat roll has a diameter of 275mm. The mat roll is wrapped up

with plastic film,and then packed in a cardboard box or wrapped up

with kraft paper. The rolls can be vertically or horizontally

placed. For transportation, the rolls can be loaded into a

cantainer directly or on pallets. Company Profile Our

Advantages1) a short lead-time ( 10-15days ). 2) Low price can be

offered to you because we are not only a trade company but a

manufacturer. We have our factory. 3) We insure you a good

after-sale service, please get back if you have any questions. 4)

10 years working experiences specializing in the production and

sale of Fiberglass and other related products. 5) Professional

staff are provided to response all your inquiries in English. 6) We

have gained great reputation in our customers and possessed more

packaging material market. 7) Our business relationship will be

confidential to any third parties. 8) Llyod's Register and DNV

certificate can guarantee our products' safety. Company

InformationChina Beihai Group has three factories with 2100 workers

specialize in producing fiberglass products in China. We produce

the E-glass and C-glass fiberglass roving, fiberglass chopped

strands, fiberglass continuous mats, fiberglass stitch combo mats

and stitch chopped mats, powder and emulsion fiberglass chopped

strand mats, fiberglass woven roving and electronic fiberglass yarn

and fabrics with over 18 categories and 300 specifications.

Especially, China Beihai has owned the proprietary world-class core

technologies for large E-glass fiber furnaces and 3 production

lines (width of 1600mm, 2600mm and 3200mm) for producing

fiberglassChopped strand mat and 120 weaving equipments for

producing fiberglass woven roving. The annual output of fiberglass

roving reaches 380, 000 tons and fiberglass chopped strand mat 66,

000 tons and fiberglass woven roving 33, 000 tons.

FAQ1.Moq:1000kgs 2.Delivery time:15days after confirm

order3.Payment term:T/T 30% deposit in advance,70% balance

before shipment date./* January 22, 2024 19:08:37

*/!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Mass Production Glass Fibre Chopped Strand Mat for Boats

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup