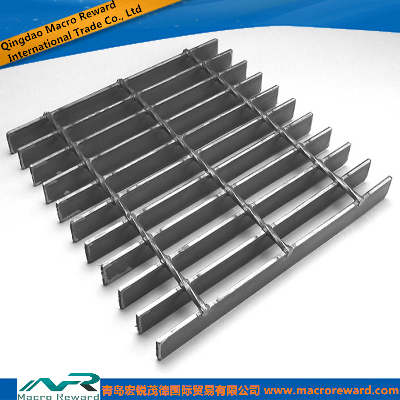

Steel Bar GratingSteel bar grating is manufactured from ASTM A-1011

mild carbon steel and is available in three distinct products: type

" W" welded bar grating, type " DT" dovetail pressure locked

grating, and type " SL" swage locked grating. All three products

are available with bearing bar spacing ranging from 19/16"

(1-3/16") to 7/16" on center and cross bars at either 4" or 2" on

center. Each product has a standard plain surface or may

be specified with optional serrated or Algrip surfaces. Finish

options include bare steel, painted, hot dip galvanized, or

specialty coatings. The steel bar grating load tables provide

detailed specification information related to these

products. Type "W" Welded Steel GratingOur most economical

steel grating products, type "W" welded steel gratings are

manufactured by forge welding rectangular bearing bars and drawn

cross bars. This welding process provides a positive fused

connection providing years of service under the most demanding

conditions. Type 19-W-4 steel grating is our most popular product

and is recommended for nearly all industrial flooring

applications. With nearly 80% open area, 19-W-4 allows for the

easy passage of dirt, debris, snow, and liquids and is essentially

self-cleaning. Type "W" gratings are available in close mesh, ADA

conforming spacings 11-W-4 and 7-W-4 which are commonly used in

public areas. When specifying type 11-W-4 for ADA applications,

3/16" thick bearing bars must be specified. Type "DT" Dovetail

Pressure Locked Steel Grating Type "DT" steel gratings have

deep rectangular cross bars and are manufactured by inserting

pre-punched bearing bars and cross bars into an "egg-crate"

configuration and deforming the cross bars under intense hydraulic

pressure. The deep cross bars on type "DT" gratings make them

popular for architectural applications such as sun shades and

infill panels with the deeper cross bar serving as a distinct

architectural accent. Type "SL" Swage LockedSteel GratingType

"SL" steel gratings are manufactured by inserting hollow tube cross

bars into pre-punched holes in the bearing bars. The cross bars are

then swaged forming a positive mechanical connection. The

cross bars are recessed below the top surface of the bearing bars

providing a uniform and attractive architectural

appearance. Swage locking is a particularly efficient

process for the production of close mesh gratings. Type 7-SL-4 with

3/16" thick bearing bars provides a net 1/4" clear opening

between the bearing bars. This narrow opening is often preferred in

public areas where concerns of drainage and the presence of high

heeled shoes converge. /* January 22, 2024 19:08:37

*/!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about ASTM Steel Bar Grating Heavy Duty Grating

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup