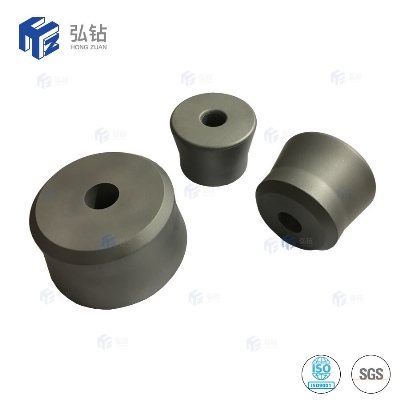

Feature:Tungsten Carbide wire drawing nibs was pressed into steel

holder, to work as a wire drawing die, which was widely used in the

production of wire, cable, tube, and other related products. As the

parameters of tungsten carbide, the dies can last longer time and

need less replacement and maintain, which make it more profitable

for users. As there're many different kinds of wire/tube/rod

products, there're various kinds of different wire drawing dies and

nibs, including types S11 series, S12 series, S13 series, W series,

WTA series, R series, etc. 1. Used for making high

temperature parts, wear parts, anti-shielding parts and

corrosion-resistant parts.2. Used in making hardware and standard

stamping moulds.3. Applicable for electronic industry, motor rotor,

stator, LED lead frame, EI silicon sheet and so on.4. Used for

producing drawn mold, wear-resistant parts, stamping parts and

automatic press with punch.5. Used for stamping die, extrusion die,

stamping molds.6. Drawing many kinds of steel wire, aluminum wire,

high carbon, MS wire etcAdvantage of Tungsten Carbide Dies1.

Material:100% virgin raw material with submicron grain size2.

Grade: Various grades for choice3. Advanced production equipments

and testing equipments4. Precious Ground and polished5. High wear

resistance,high hardness and impact toughness6. Advanced

technology, automatic pressing, HIP sintering and precision

grinding7. Samples & small orders are acceptable.Common shape and

size check

below:TypeDHdhα°S11-860.3-1.00.3-0.614°1080.7-1.40.3-0.614°13100.4-2.80.3-1.616°15130.5-3.00.3-1.416°16140.4-3.80.3-1.816°20171.2-4.72.0-2.618°21171.8-5.71.2-3.018°22181.7-6.41.2-3.018°For

any other sizes we are able to custom-made according to clients'

requirements or drawings.Recommend grades and specifications:Grade

No.Density(g/cm3)HRAT.R.S(Mpa)ApplicationYG3X14.9≥91.5≥1300For

drawing non-ferrous metal wire and stainless-steel wire

etc.YG614.8≥90.0≥2150For drawing steel wire and stainless-steel

wire etc.YG6X14.8≥92.0≥1860For drawing nonferrous metal wire, steel

wire, stainless steel wire. Good wear resistance and high

toughness.YG814.8≥89.5≥2320For drawing steel wire, stainless steel

wire. Good general performance.YG1114.4≥88.5≥2420For fabricating

drawing dies of steel tubes and rods under high compressibility

ratio; punching, stamping, forging tools under large

stress.Application:1. Tungsten carbide with high hardness, high

wear resistance and high red hardness, at 550ºC still maintain more

than 56HRC hardness.2. Has a high modulus of elasticity, generally

is (4~7)×104kg / mm2, and excellent rigidity at room temperature.3.

Have a high compressive strength which is greater than 6000MPa.4.

Have good resistance to oxidation and corrosion resistance, acid

resistance, alkali resistance and high temperature not easily

oxidized.5. Has a low coefficient of thermal expansion, suitable

for manufacturing high, precision, sharp die.Company ProfileZhuZhou

HongTong Tungsten Carbide Co., Ltd.,specialized in production

carbide products more than 20 years and located in the hometown of

tungsten carbide in China. We can manufacture all kind of tungsten

carbide products. Our products are utilized in industrial,

aerospace, machining, metallurgy, oil drilling, mining tools,

electronic communications, construction applications. Now we are

exporting to 46 countries. including USA, Russian , India , Italy,

Poland ,France,Brazil etc . We have a professional QC team follow

to the System of ISO9001:2015, Covering the Raw Materials Incoming,

Production Processes,Finished Products and Packaging to ensure high

quality products output.We mainly produce Tungsten Carbide Ball and

Seat, Agriculture wear parts plates, Carbide tips, Carbide tiles,

HPGR Stud pins, Brazed Inserts, Gripper Pads, Buttons, VSI Bars,

Rod, Strips, PDC substrate, Weld on teeth, Bushings, Wire Drawing

Dies, Heading Dies, Seal Ring, Nozzles, and other customized

carbide products.Product packagingFAQQ1 : Are you Factory or

trading company ?We are Factory with 20 years of production

experience.Q2: What is the producing process?Production process

including raw material cutting, machine processing, grinding,

accessories cleaning, assemble, cleaning,stoving, oil coating,

cover pressing, testing, package.Q3: How to control the products

quality? All products will be tested before bulk production, and we

will check the physical properties, shape and tolerance for

ensuring qualified products before shipping.Q4: What is the

transportation?If small quantity , we Suggest to send by express,

such as DHL,UPS, TNT FEDEX. If large quantity, by sea.Q5: Can you

provide OEM service?Yes, we work on OEM orders. Which means size,

quantity, design, packing solution, etc will depend on your

requests; and your logo will be customized on our productsQ6: How

to place an order for Good performance nonstandard products by

stellite alloy? 1. Fill your Order List in our onlineInquiry System

(Also you can directly contact our salesperson by

Related products about Blank Tungsten Alloy Carbide Industrial Semi Floating Plug

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup