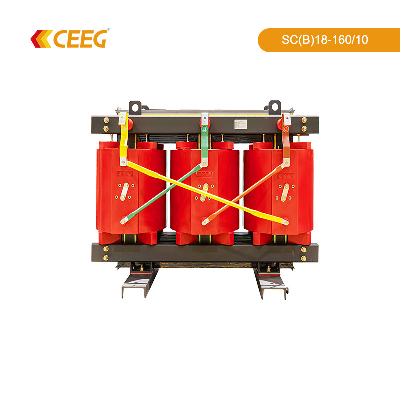

Product Description FEATURES . High quality and high permeability

silicon steel with a multi-stage stepping process leads to low

no-load loss.2. The surface adopting nano paint self-leveling

process leads to low noise.3. Strong waterproof and short-circuit

resistance, strong overload capacity, good electrical performance,

safety, and reliability.4. Through the simulation analysis of the

electric field, temperature field, and magnetic field, CEEG is the

first company in China to pass KEMA's E2, C2, and F1 tests.5. The

product can adopt a dual-mode structure scheme to meet the needs of

different customer groups.6. Special intelligent transformer

solutions and big data cloud diagnosis technology are adopted to be

online from time to time.SpecificationSCB 18-100~2500/10Rated High

Voltage:10(10.5,11,6.6,6.3,6)kV

Connection Symbol:Dyn11/Yyn0Nominal Low-voltage:0.4kV Tapping

Range:±2×2.5% Model No. UK

%Air loss PO(W)Load loss ( 75ºC) PK(W) IO ( %)LPA (AN )

dB Gauge m*nSIZEL*B*H(mm)Enclosure Size(top

outgoing line)(footing included)Enclosure Size (side

outgoing line) (footing included)Transport PackageHS

CodeSC(B)18-100/10423012400.742550×5501050×750×7901700×1400×16001700×1400×2200International

Wooden Case or According to Client′s

requirements8504349000SC(B)18-125/10427014500.742550×5501050×750×8301700×1400×16001700×1400×2200 SC(B)18-160/10431016700.742550×5501100×750×8801700×1400×16001700×1400×2200 SC(B)18-200/10436019900.743550×5501090×750×9001700×1400×16001700×1400×2200 SC(B)18-250/10441521700.743660×6601150×860×9401700×1400×16001700×1400×2200 SC(B)18-315/10451027300.745660×6601180×860×9701700×1400×16001700×1400×2200 SC(B)18-400/10457031400.745660×6601290×860×9901700×1400×16001700×1400×2200 SC(B)18-500/10467038300.646660×6601260×860×10301700×1400×16001700×1400×2200 SC(B)18-630/10477546100.646820×6601300×860×11201900×1500×18001900×1500×2200 SC(B)18-630/10675046900.646820×6601390×860×10601900×1500×18001900×1500×2200 SC(B)18-800/10687554700.449820×8201450×1020×10701900×1500×18001900×1500×2200 SC(B)18-1000/106102064300.450820×8201510×1020×11101900×1500×18001900×1500×2200 SC(B)18-1250/106120576100.451820×8201540×1020×11602000×1600×20002000×1600×2200 SC(B)18-1600/106141592300.351820×10701650×1150×12302000×1600×20002000×1600×2200 SC(B)18-2000/1061760114200.3521070×10701730×1150×13302200×1600×22002200×1600×2200 SC(B)18-2500/1062080135400.3531070×10701810×1150×13702200×1600×22002200×1600×2200 SC(B)18-1600/1081415101600.351820×10701650×1150×11902000×1600×20002000×1600×2200 SC(B)18-2000/1081760125300.3521070×10701730×1150×13002200×1600×22002200×1600×2200 SC(B)18-2500/1082080148300.3531070×10701810×1150×13202200×1600×22002200×1600×2200 Detailed

Photos Certifications CERTIFICATED & QUALIFIED SCB series cast

resin dry-type transformers have reached the first-level energy

efficiency standard of GB20052-2020, and won the 3C, PCCC

energy-saving certification, ISO-9001, ISO-45001, and ISO-14001

certificates.CEEG's cast resin dry-type power transformers have

been widely adopted in key projects by customers from all over the

world. For example, they have been chosen to serve in the Qingdao

International Sailing Center, Beijing Urban sub-Center, Beijing

Stadium the Skating Hall, Nanjing Metro, Shanghai EXPO Exhibition

Center, etc. Our Advantages DESIGN & MANUFACTURE

PROCESS Based on more than 30 years of design, manufacturing, and

experimental experience in the transformer industry, CEEG has

developed a set of advanced three-dimensional + parametric design

software, which can realize automatic design, cost optimization,

and simulation.Fully considering the requirements of the national

and industrial standards, ensuring the advantageous design of

products.The high-voltage winding conductor is wound with a

high-quality conductor and reinforced with long and short-cut glass

fiber felt. Poured by the advanced Heidrich vacuum pouring system

under vacuum. Effectively restrain the occurrence of partial

discharge, and the partial discharge is ≤ 5pc.The low-voltage

winding adopts a high-quality foil conductor and is wound on an

automatic foil winding machine. The foil winding machine adopts the

patented technology of foil wire hydraulic energy-saving tension

crimping device, high-precision detection of ±0.5mm, and advanced

argon arc welding technology, which plays a key role in ensuring

the quality of coil winding.The iron core adopts a high-quality

high magnetic conductivity-oriented silicon steel sheet, a 45° full

oblique step lapping process, and the surface adopts special

moisture-proof and rust-proof coating, which effectively reduces

the no-load current and noise level.Product Test TESTING All

products strictly control the production process and quality links,

and conduct strict tests and inspections according to national

standards and customized requirements before leaving the factory,

including partial discharge inspection, lightning resistance and

electric shock inspection, noise inspection, and other ne

Related products about 160kVA/10kv Enhancing Grid Stability with Medium Voltage Resin-Cast Transformers

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup