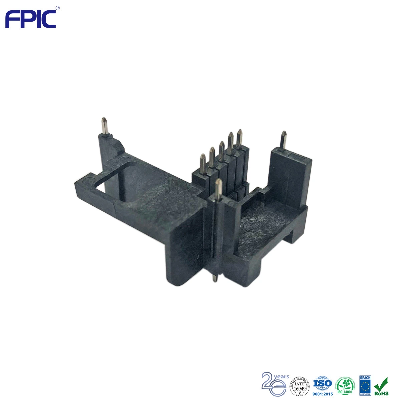

One stop fabrication manufacturer Automobile board to board

connectors Forman has been fabricating electronics components

since 1999 and we offer one-stop services from design concept, mold

manufacture, plastic injection, metal stamping, and final assembly

services. Product DescriptionProduct Design

SpecificationProduct DescriptionCustomized automotive/automobile

electric connector componentsMaterial OptionInsulator Housing: PBT,

LCP, PA66, PA66+glass fiber 30%, PA9T, etc.Contact Terminal: C7025,

C5191, C2680, H65, etc.Ground lug: C5191, C2680, etc.Plating

OptionHigh Temperature Matt Tin Plating Over Nickel, Gold plating

on contact area, tin plating on soldring area, etc.Product Assembly

MethodAutomatic Pin/Terminal Inserting Method or Injection molding

terminal/pinProduct ApplicationAutomotive OBD Moudle, PCB board pin

panel for window lifting system, Wireless Charging, etc.Product

Development Schedule30 Days for the mould making and first

prototype + 30 Days for PPAP document and testing. The first

batch will take 10~15 working days and the further will only take 7

working days.Product Sample Range Development FlowProduct

Evaluation ProcessEvaluation DetailsDevelopment SchedulePPAP File

SampleCompany Profile Shenzhen Forman Precision

Industry Co., Ltd(Abbreviation FPIC) has always been committed to

the research, development and manufacture of OEM automotive

components, energy storage connectors, electronic connectors, wire

harnesses, thermal modules, plastic parts and metal parts since

1999. FPIC has been attaching importance to scientific

production and efficient quality control, we have introduced the

ISO9001, ISO14001, and IATF16949 management systems, also the ERP

and MES production control systems. Nowadays, we have our own

R&D Center, Testing Center, and Production Departments for

Mould-Making, Injection Molding, Stamping, and

Assembly. Insisting on the philosophy of "Focus on

Customer, Contributor Based, and Always Going All Out", FPIC offers

good quality controlling capability, super flexible delivery, and

continuous cost optimization, we look forward to working together

with you for mutual development and benefits.Total EmployeeMore

than 200 people ServicesDesign concepts, Plastic injection,

Metal Stamping, and Assembly R&D TeamYes, there are 30

engineers in our R&D department and all of them are studied the

related profession with rich experience in

electronics. Operation SystemERPQuality Assurance100% CCD

quality inspection and spot check by our QC team. We have a strict

quality management system from raw material to final products, also

there is a professional Laboratory in our factory to finish most

kinds of tests. Our Advantage:1:Strong Full-Auto Production

Competence2:100% Quality Inspection from raw material to finish

products.3:Over 20 years of manufacturing experience and

our capital of more than RMB50,000,0004:All of our employees

must finish operation training class before running into production

and each month we will have a new training class to improve skills,

teach them safe operation and so on.5:Forman has passed ISO9001,

ISO14001, and IATF16949 Certificates, all our operations meet

Chinese Politics and Environment Protections.Plant Details

Production AreaWorkshop Display:Production CapacityQuality

ManagementMaterial TrackingEvery material will post a label when

it's finished, it's easy for us to see the part number, material,

qty, date, and other information.Process inspectionWe verify the

material reliability in the designing stage, then control every

process will strictly comply with all quality systems for best

quality in production. Testing CenterForman clearly

understands the quality importance for a company, therefore, every

aspect from product designing, producing, to inspecting has been

paid attention to.Testing Equipment ListFAQFAQ:Q: Where is your

factory and do you have any certificates? A: Our factory is

located in Gongming town, Shenzhen and we have passed ISO9001,

ISO14000 and TS16949.Q: Do you have any qty limited? A:

Firstly for our stock products, we can arrange the shipment

according to your requirement and for the specialized one, it

depends on the production cost.Q: Can you please talk about your

quality assurance? A: FPI completely controls the income and

outcome material according to the ISO system and 100% check for our

parts by instrument, QC will spot check in each process at least

per 2 hours, and before shipment, our OQC will arrange the

inspection again.Q: What's kinds of information you need for a

quote? A: In order to quote for you earlier, please provide us

the details together with your inquiry. 1. 3D drawings (STEP,

CAD, SOLID Works, PROE, DXF and PDF) 2. Material requirement

(include contact material and insulation material.) 3. Surface

treatment 4. Quantity or Consumption (per order/

per month/ annual) 5. Any special demands or requirements,

such as packing, labels, delivery, etc.Forman warmly welcomes your

inquiry and visit for more d

Related products about One Stop Fabrication Manufacturer Automobile Board to Board Connectors

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup