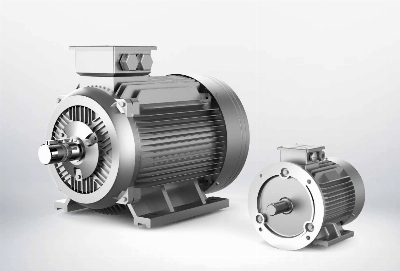

IntroductionMV31 series low-voltage permanent magnet synchronous

motor is a general-purpose industrial motor with high efficiency,

energy saving, high power density and high reliability. It can be

widely used in plastic machinery, metal products, ceramic

machinery, transmission machinery and other industries.Technical

Parameters:Rated voltage: 380VPower range: 3-400kWRated speed:

3000rpm, 1500rpm, 1000rpm, 750rpmInstallation location: Indoor (can

be customized)Ambient temperature: minus 15 degrees - 40 degrees (

can be customized)Altitude: 1000 meters( can be

customized)Protection level: IP55 (IP54-100L and below

frame)Short-term overload: no more than 1.7 times the rated

torqueMotor working system: S1Insulation class: FThermal

protection: PTCMotor energy efficiency: IE4 (above 90kW)/GB1 (90kW

and below)Over-speed range: -not exceed 1.2 times the rated

speedEncoder: standard none; optional A3 or U1Cooling method: IC411

(TEFC); optional IC416 (TEBC)Installation method: B3, B35, B5, V1

(for other specifications, please consult the drive motor

SPDT)Brake: None (not planned for now)Inverter: optional inverter

to achieve the best use effectsystem topologyfeaturesLow noise, low

vibration, light weight, small size, long bearing life, high

reliability, and strong versatilityNoise can be reduced by 5-15dB

compared with asynchronous motorVibration up to class BCompared

with asynchronous motors with the same output power, the frame size

is reduced by 1 to 3, and the weight is reduced by about

40%.Optimize the bearing design, select high-quality bearings,

adopt oil-injectable structure for 180 frames and above, and adopt

anti-shaft current measures for 250 frames (or 110kW) and above,

greatly improving bearing lifeHigh-strength castings and machining

precision ensure higher mechanical strengthImplementation of

failure rate of quality standard 1000PPMIt can be replaced equally

with ordinary asynchronous motorsAdvantageCompared with

asynchronous motor or reluctance motor, the efficiency of permanent

magnet motor has little effect on the change of load.-- For

variable torque loads (fans, pumps, fluids), constant torque loads

(screw compressors, extruders, etc.) are preferredpermanent magnet

synchronous motor.-- For project transformation, according to

different application scenarios, the newly invested permanent

magnet synchronous motor can recover the cost of the whole machine

within 1-2 years.-- For new motor projects, the additional

investment cost compared with GB3 asynchronous motors of the same

power can be recovered within 3-6 months./* January 22, 2024

19:08:37 */!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Low Voltage Three Phase Permanent Magnetic Synchronous Motor

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup