Certifications FAQQ: What're your main products?A: DC

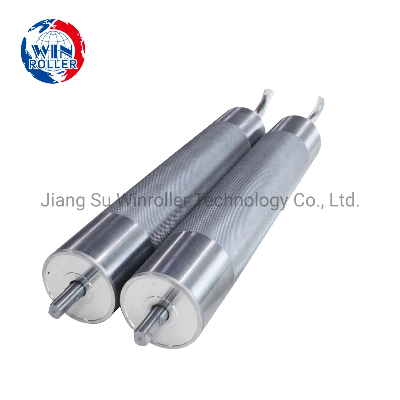

brushless motor roller/AC 3ph motor roller/Direct drive motor

roller/Oil immersed motor roller/Gear reduction motor/controller

boxQ: How to select a suitable motor roller?A:If you have motor

roller pictures or drawings to show us, or you have detailed specs

like conveyor mode(pallet or belt),linear speed,loading

weight,loading object material,roller

diameter,length,voltage and noise level etc, then we can

recommend suitable motor roller to you.Q: Do you have a customized

service for your standard motor rollers?A: Yes, we can customize.Q:

Do you have an individual design service for motor rollers?A: Yes,

we would like to design roller individually for our

customers. Q: What's your lead time?A: Generally speaking, our

regular standard product will need 7~15days, a bit longer for

customized products. But we are very flexible on the lead time, it

will depend on the specific orders.The electric drum is a drum with

its own power, which is reasonably installed inside the steel pipe

after integrating the motor, gear reducer and sensor. Therefore,

the motor, chain, intermediate shaft or other auxiliary drive

components are not considered for the conveying system; No need for

bulky gearbox. Just install the electric roller on the rack,

connect the wire to the power supply, and the work is completed.

The conveying system is more simple, intelligent, beautiful, safe

and reliable.The products are widely used in food processing,

pharmaceutical production, electronic assembly, airport logistics,

postal services, distribution and various industries. It meets the

diversified and automatic needs of different industries. Product

quality, technology, credit and service are praised by customers,

and it is an advanced R&D and production enterprise in the

industryDry DG, oil immersed OG and direct drive FO motor sights

meet different application scenariosHigh torqueThe combination of

new efficient motor and high-precision gear brings the best

performance electric rollerSave timeCompared with the transmission

gear motor, the number of parts required for driving is

significantly reduced, so the design, parts procurement and

assembly time can be shortened.High velocityFrom minimum 1/MIN to

maximum 300M/MINReduce control workloadVarious driving functions,

such as area management logic, sensor signal input function,

acceleration/deceleration time adjustment, can significantly reduce

the control and wiring time. In addition, the speed can be

adjusted, so it can flexibly respond to customer requirements.Low

noiseCompared with traditional products, the noise level is reduced

by about 10%SecurityDC 24V safety voltage.Space savingBy using

elastic shaft, installation is simplified and maintenance is

convenientConvenientIt is easy to replace and maintenance free/*

January 22, 2024 19:08:37 */!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Winroller AC Motor S304 Sprocket Conveyor Motorized Roller for Concrete Conveyor

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup