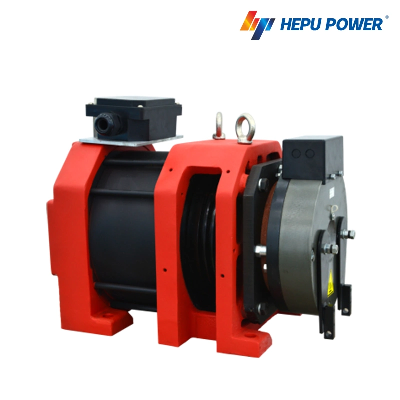

Product DescriptionOur gearless traction machine has been designed

for various capacity and speedwhich meet different customer's

requirements.It is a mechatronics product which can be divided to

internal rotor structure andexternal rotor structure. It consists

of stator, rotor, brake and encoder.The traction machine is

assembled with silicon-steel lamination which insulationis F class.

We use Neodymium iron boron (NdFeB), the best material for

magnet.The traction sheave is cast by nodular iron and which type

is QT700-2.The protection class of traction machine is IP41 for

WTD1 and WTD1-B series,IP40 for WTD2-P series; Noise class≤55dB;

Acceleration vibration ≤ 0.45mm/s.The traction machine mainly

consists of stator frame, stator core, rotor, tractionsheave, brake

pad, brake and encoder. The stator core is fixed to the stator

frame.The traction sheave is assembled into the rotor and there are

20 poles of magnetsare evenly distributed to the rotor.To fix the

rotation shaft and the rotor together and fix to the stator frame

throughthe bearing. The traction sheave is assembled to the front

of the rotation shaftwhich is the critical part to bear the whole

weight of the lift. Encoder will beassembled to the back of the

shaft. Power supply wiring and temperature controllerare fixed

inside the traction wiring connection box.It achieves the brake

function through the contact between friction plate and

brakewheel.Detailed Photos Product Parameters Company

ProfileHepu Power Co.,Ltd. Hepu Power Co.,Ltd. was founded in

March,2010. It is a national Hi-Tech enterprise which specialized

in providing energy-saving system. Hepu Power Co., Ltd.

consists of Hepu Power (Guangdong) Co., Ltd., Hepu Power (Jiangsu)

Co., Ltd., and Hepu Power (Shenzhen) Co., Ltd. The headquarters is

located at No. 26, Yingbin Avenue, National High-tech Zone,

Zhaoqing, Guangdong. The company can annually produce 250,000

electric vehicle powertrains, 300,000 electric vehicle motors, and

300,000 controllers. Hepu Power has a high-quality

technical R&D team of more than 120 people, with high-tech

talents selected from the National Ten Thousand Talents Program,

National Science and Technology Innovation and Entrepreneurship

Talents, Guangdong Science and Technology Entrepreneurship Leaders,

Xijiang Top Talents, and Xijiang Scarce Talents. And independently

developed electric vehicle powertrains, permanent magnet

synchronous motors, AC asynchronous motors, permanent magnet

synchronous controllers, AC asynchronous controllers and other

products, serving electric passenger cars, electric logistics

vehicles, electric buses, electric minibuses, New energy vehicle

industries such as electric forklifts, electric engineering

vehicles, and electric logistics vehicles. Hepu Power has mastered

the core technologies of electric vehicle motors, controllers,

reducers and powertrains, established the Guangdong Engineering

Technology R&D Center, and listed the Guangdong Provincial Key

Laboratory, with more than 120 sets of experimental benches and

experimental equipment. Design and development, performance

verification, durability test, IP67 waterproof and dustproof test,

mechanical vibration test, mechanical shock test, and full working

conditions NVH experiment, high and low temperature cyclic impact

experiment, high and low temperature loading operation experiment

and other product design verification and testing

capabilities. Hepu Power has built an electric vehicle

powertrain automated assembly workshop, an electric motor automated

assembly workshop, a controller SMT automatic placement workshop,

an automated winding and embedding workshop, a casting processing

center, an online spraying center, a complete machine performance

digital inspection center, and Created a zero-defect quality

assurance system to provide customers with perfect products and

high-quality services. Hepu Power has obtained the automotive

industry IATF16949:2016 quality management system certification,

ISO9001:2015 quality management system certification, ISO14001:2015

environmental management system certification, ISO45001:2018

occupational health and safety management system certification, EU

product safety CE certification, and U.S. product safety

Performance UL certification, Korean electrical product safety KC

certification, etc. At present, the company has formed a

research and development platform suitable for six categories of

electric drive products such as pure electric passenger vehicles,

pure electric commercial vehicles, pure electric special vehicles,

extended-range hybrids, electric vehicles, and intelligent unmanned

vehicles, forming a 1.2kw- 500kw power series products, supporting

the development of more than 260 varieties of electric power system

products for domestic and foreign vehicle companies and power

system integrators. In terms of application in the electric vehicle

market, the company's products are used in electric vehicles such

as FIAT, Xpeng, BAIC, Geely, BYD, Ch

Related products about Permanent Magnet Synchronous Gearless Elevator Traction Machine 450kgs Motor Engine

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup