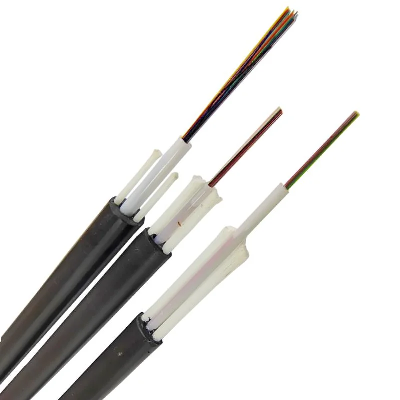

Product Description GYFTY Optical

cable Application This cable is ideal

for long distance and inter-office communication in strong current

zone, as well as power transmission system. The built in suspension

stranded rope provides high tensile strength, enabling the cable

suited for large span installation, resulting in time and

installation cost savings. The suspension wire, being an integral

part of the cable, is easily available for gripping, fastening and

pulling. This cable is featured of its lightness, low dispersion

and high tensile strength.

Description The cable consists of 2 to 36 fibers

containing tubes or fillers stranded in up to 3 layers around

a central strength member and bound under a PE jacket.

Each jelly filled tube contains 4 -12 fibers. Solid or stranded

steel wire coated with polyethylene is usually used as central

strength member. Fiber glass reinforced plastics (FRP) will be used

as central strength member if non metallic construction is

required. Either aramid yarn or fiber glass is wound around the tube

to provide physical protection and tensile strength. Water blocking

materials are filled in the interstice of the cable core, core

wrapping layer/water blocking tape. The cable can be jacketed with

either PE, PVC or LSZH though PE is the preferred option for water

protection purpose. For direct burial, steel wire armour or

corrugated steel tape armour is applied with an optional inner

jacket of either PVC or PE. An optional Aluminium moisture tape can

be incorporated under the jacket for water blocking and shielding

purpose. Cable cores are connected with the suspension wires by PE

sheath to form a figure "8" shape. An optional ripcord is

located under the jacket to facilitate jacket removal. Product

Parameters Physical PropertiesFiber CountNominal

Weight(kg/km)Nominal Weight(lb/kft)Nominal Outer

Diameter(mm)Nominal Outer Diameter(in)Maximum Pulling

LoadInstallation(N/Ib)In

Service(N/Ib)2-24389.0261.0712.6*25.10.50*0.992670/600890/20036-72429.0287.9214.7*27.10.58*1.072670/600890/20096-144571.0383.2220.2*32.60.80*1.292670/600890/2002-24303.0203.369.1*21.50.36*0.852670/600890/20036-72332.0222.8211.1*23.50.44*0.932670/600890/20096-144417.0279.8715.9*28.30.63*1.122670/600890/200 Physical

Properties Fiber CountNominal Weight(kg/km)Nominal

Weight(lb/kft)Nominal Outer Diameter(mm)Nominal Outer

Diameter(in)Maximum Pulling LoadInstallation(N/Ib)In

Service(N/Ib)2-24389.0261.0712.6*25.10.50*0.992670/600890/20036-72429.0287.9214.7*27.10.58*1.072670/600890/20096-144571.0383.2220.2*32.60.80*1.292670/600890/200 Mechanical

Properties Minimum Bending Radius: Maximum Compressive

Load:4000N for unarmored cables;Under installation:20×OD 6000N

for armoured cablesDuring operation0×OD for unarmoured

cablesRepeated Impact:4.4 N.m (J) 20×OD for armoured

cablesTwist (Torsion):180×10 times, 125×ODTemperature

Range: Cyclic Flexing:25 cycles for armoured cables.Operating

Temperature Range:-40ºC(-40ºF) to +70ºC(+158ºF) 100 cycles for

unarmoured cables.Storage Temperature Range:-50ºC(-58ºF) to

+70ºC(+158ºF)Crush Resistance:220N/cm

(125lb/in) Fiber Compliance Temperature

Cycling Tensile Strength Crush Impact Repeated

Bending Torsion Kink Cable Bend Cool

BendIEC60794-1-2-F2 IEC60794-1-2-E1AIEC60794-1-2-E3 IEC60794-1-2-E4 IEC60794-1-2-E6 IEC60794-1-2-E7 IEC60794-1-2-E10 IEC60794-1-2-E11 IEC60794-1-2-E11 Safety

Compliance General Purpose GradeFlammability Test: OFN

(UL1581)Riser GradeFlammability Test: OFNR/FT4 (UL1666)Plenum

GradeFlammability Test: OFNP/FT6 (UL 910)FRPVC GradeFlammability

Test: IEC60332-1LSZH GradeHalogen Content Test: IEC

60754-1 Acidity Test: IEC 60754; Smoke Emission Test:

IEC61034-1/2LSFROH Grade Halogen Content Test: IEC

60754-1 Acidity Test: IEC 60754; Smoke Emission Test:

IEC61034-1/2 Flammability Test: IEC60332-1 & IEC

60332-3C/AFR GradeFire Resistance Test : IEC 60331 / BS

6387 CWDetailed PhotosCompany ProfileABOUT USZhejiang Hanli Cable

Co., Ltd. is a professional manufacturer of tv cables and cable

television network equipment. It has more than 300 employees,

including 100 engineers with college degree or above, and more than

50 directly engaged in high-tech and new product research and

development. And has a production site of more than 38,000 square

meters, 12 domestic and imported production equipment, and a number

of advanced cable testing equipment. The company's

leading products include SYWV(Y)-75 series physical high foaming RF

coaxial cableRG series access network coaxial cableSYWLY-75 series

aluminum tube cable,digital communication cable and digital

monitoring lineetc sold abroad. The company's technology center

mainly develops new productsnew processes and new technologies, and

has successively developed more than 30 provincial-level new

products of which 26 have obtained national patents,and ten

products have been identified as high-tech products in Zhejiang

Province. This project was identified as a National Torch Program

project. In the futurethe company will c

Related products about Outdoor Fiber Optic Communication Connector GYFTY Duct Cable

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup