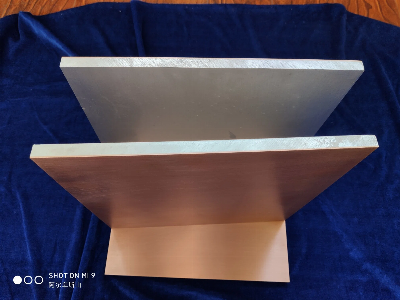

Titanium clad copper bars/sheets/pipes/wire and other

non-ferrous metals clad composite materials.COPPER CLAD ALUNINUM

PLATE/ STEEL CLAD STEEL PLATE/ COPPER CLAD STEEL PLATE/ TITANIUM

CLAD STEEL PALTE /ALUNINUM CLAD STEEL PLATE FOR Transition joint

plate blockThe copper and aluminum are excellent conductive

materials with high cost performance. They are widely used in power

systems and are the main conductive materials.In general, the

aluminum is used in the high voltage line, and the copper is used

in low voltage distribution cabinet systems.However, the copper and

aluminum cannot be directly connected. Therefore,the reliable

connection between copper conductor and aluminum conductor has a

significant impact on the safe operation of the whole power

system.The traditional copper-aluminum connecting materials are

usually prepared by the flash welding, friction welding and brazing

processes. There is the quality risk and the potential safety

hazard for the mechanical properties, reliability and electrical

conductivity of the connectors.It is imperative to develop an

advanced production technology and a new type of electric fittings

materials.Our company develops the copper clad aluminum composite

equipment clamp, parallel groove clamp, copper clad aluminum

composite transition plate and copper clad aluminum composite

connecting sheet by the independent innovation. They are widely

used in the electric industry for the replacement of the

traditional process, to not only improve the product quality, but

also reduce the production cost. Therefore, it is an ideal

connecting products of copper clad aluminum transition

plate.Product SizeThickness:3.0~15.0mm;Width:≤1000mmProduct

FeaturesIt is high bonding strength, to realize the metallurgical

bonding between copper and aluminum, solve the problems of low

conductivity, low mechanical strength, poor reliability and low

density of copper and aluminum connectors, and save the cost and

resources.Technical ParametersBonding strength:≥12N/mm;Bonding

rate: 100%;Shear strength:≥35MPa;Tensile strength:

90~150MPa;Elongation rate:

0~35% COPPER

ALD ALUNINUM PLATE FOR CONDUCTIVE BUSBARProduct

SizeThickness3.0~15.0mm;Width≤500mm.Product FeaturesThe copper clad

aluminum composite bars produced by our company with several

patented technologies solves two major problems of copper clad

aluminum composites, such as easy oxidation of copper and aluminum,

difficult removal of oxide film, and inter metallic compound

(Al2Cu) between copper and aluminum at lower temperature. The

thickness of copper-aluminum transition layer for the traditional

copper clad aluminum bar is 15 - 50μm through the SEM analysis,

while the thickness of copper-aluminum transition layer for the

copper clad aluminum composite bar produced by our company is only

1-2um, which is much less than that of traditional copper clad

aluminum bar. It not only realizes the metallurgical bonding

between copper and aluminum, but also ensures the bonding strength

between copper and aluminum effectively, to solve the problem of

high resistivity for the transition layer. Its overall performance

is excellent, the bending, drilling and punching performance are

the same as that of pure copper, and the density is small, and it

can save more than 30% of cost in use.Technical ParametersBonding

strength:≥12N/mmBonding rate: 100%Shear strength:≥35MPaTensile

strength: 90~150MPaElongation rate: 0~35%DC

resistivity:≤0.02450mm2/mSurface conductivity:≥98%Rated current

temperature rise:≤65ºCMain scope of applicationElectric

conductivity industry (can be widely used in high and low voltage

distribution cabinet, switch gear, bus-bar and electrolyzer).

Titanium clad copper bus bars is a copper bar

cladding with a certain thickness of titanium level, mainly

used as a stand in plating, electrolysis, hydrometallurgy

processes, because it has not only the original conductive property

of the copper bar, but also protecting the copper bar from corroded

by titanium level, therefore avoid the traditional copper bus bars

shortcomings: danger and difficulty changing the anode metals,

copper bar corrosion, heat generation caused by the electrical

contact resistance in electrolysis and plating defects due to

corroded and fallen copper compound, can greatly lower pollution of

electrolyte. Now, the submerged Ti clad copper bus bar is the

best choice for many industries including print circuit makers,

steel (copper, gold) refining manufacturers. Normally, we

provide the first rate clad non-ferrous metal composites,

mainly titanium clad copper and also including zirconium clad

copper, 316L steel clad copper, titanium clad 316L steel plates,

bars, tubes, composite wire, and multi-layer clad composites,

etc. But, if you request that the material has this

function above, then you must be sure that there are much stronger

combination strength and much higher pasting rate between the

copper bars and the titanium level

Related products about Explosion Bonding Copper Clad Aluminum/Copper Cadding Aluminum Sheet Transition Joint

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup