Specification1. ScopeThe cables are manufactured and tested in

accordance with IEC60502 Power Cables with Extruded Insulation

and their accessories for rated voltages from 1kV(Um1.2 kV) up to

30kV(Um 36kV). Whereas, Dongfeng Cable can supply

XLPE insulation cables according to other recognized national and

international standards or customized specification.2.

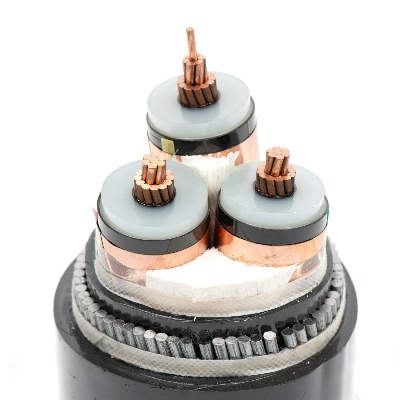

Construction and Material1) ConductorConductors are normally

class 2 of compacted cicular or circular standard

conductors of copper or aluminium. 2) Conductor

ScreenAll cable of rated voltage above 1.8/3kV are supplied

with conductor screening which is non-mentallic and consists of

either semi-conducting tape or a layer of extruded

semi-conducting compound,or a combination of the two.3)

InsulationInsulation is a layer of extruded cross-linked

polyethylene(XLPE).4) Insulation ScreenFor cable at rated

voltage above 1.8/3kV ,insulation screening consists of a

non-metallic semi-conducting part in combination with a metallic

layer and consists of either semi-conducting tape or a layer of

extruded semi-conducting compound.. The extruded insulation screen

is normally free strippable(easy removable) type but can be

provided with bonded one upon request. The metallic part

is normally applied on the individual cores for rated voltage above

1.8/3kV and on the core assembly for rated voltage

1.8/3kV and consists of plain annealed copper tape. or copper

tape screen a layer of copper wire,a lead alloy or corrugated

aluminum sheath can be provided upon request. 5) Inner

Covering or Separation Sheath(for armored cables)A layer of PVC

inner coveing is applied under the armor ,if there is no

screen.When the metallic screening and the armor are of

different metals, an extruded separation sheath of PVC is provided

in order to separate the different metals.6) Metallic ArmorThe

armor, if required, consists of single layer of round wires or

double tapes of galvanized steel or aluminum or other non-magnetic

metals. Single core cables are normally armored with aluminum(other

non-magnetic metals), because non-magnetic armor is essential

for single core cable for use on A.C circuit .7) Outer SheathAll

cable are normally provided with an extruded PVC out sheath, black

colored(class ST2). Other materials can be available upon

request,as PE , polyethylene,high flame or fire retardant PVC and

etc.8) Core Identification The multiple conductors are

identified as according IEC60502 . Cable

Marking(Customized) The following information are indicated on

the surface of the outer sheath. However, the marking can also be

customized.----voltage rating, area for cable----manufacturer's

name----year of manufacturer----lengther for

cable----etc 1 Informationa, Number of cores:1, 2, 3, 3+1, 3+2, 3+3, 4, 4+1, 4+2, 5 and so on.b, Construction:Conductor: Solid or stranded copper Insulation: Cross-linked polyethylene (XLPE) or Polyvinyl chloride (PVC) Filler: Polypropylene filament with lapped binding tape Binder: Binding tape Inner sheath: Polyvinyl chloride (PVC) Armor: Galvanized steel wire armored(SWA) or steel tape armored(STA) Sheath: Polyvinyl chloride (PVC) c, Nominal Section Area(mm2) :1.5 2.5 4 6 10 16 25 35 50 70 95 120 150 185 240 300 400 500 630 800d, Features XLPE insulated power cable does not have excellent electric, mechanical properties,

but also has powerful resistance against chemical corrosion,

heat resistance and environmental stress resistance. Its structure is simple. The long period operating temperature is +90 °C. It is convenient to use and can be laid with no restriction on different levels.XLPE insulated steel wire armored power cable: XLPE/PVC insulated power cable has a number of advantages over paper insulated and PVC insulated cable. XLPE cable has high electric strength, mechanical strength, high-aging resisting, environmental stress resisting antichemical corrosion, and it is

a

simple construction, using convenient and higher operating of long term temperature. It can be laid with no drop restriction. Various

flame-retardant and non-flame retardant XLPE cable can be manufactured with three technology(peroxide, silane and irradiation cross-linking). The flame-retardant cable covers all kinds of low-smoke low-halogen low-smoke halogen-free, and non-smoke

nonhalogenated

and three classes of A, B, C. 2 Standard:IEC60502,and BS6346, VDE, AS/NZS, UL,etc or as customer's request. 3 The Rated Voltage(kv):1st class 0.6/1 1.8/3 3.6/6 6/10 8.7/15 12/20 18/30 21/35 2nd class 1/1 3/3 6/6 8.7/10 12/15 18/20 - 26/35 4 Application:1)These cables are most suitable for direct burial or for installation on trays or ducts, Where there isrisk of mechanical damage, armored cables should be used.2) For laying in

the ground along the

route with large difference of level able to bear external mechanical forces.3.Typical

Drawing4. TestsThe finished cables meet all the appropriate test

requirments specified in

IEC60502.5.PackingRange of Business: CablesLow Voltage Pow

Related products about Three Core XLPE Insulation Steel Wire Armoured PE Sheathed Medium Voltage Cable

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup