Specification1. ScopeThe cables are manufactured and tested in

accordance with IEC60502 Power Cables with Extruded Insulation

and their accessories for rated voltages from 1kV(Um1.2 kV) up to

30kV(Um 36kV). Whereas, Dongfeng Cable can supply XLPE

insulation cables according to other recognized national and

international standards or customized specification.2.

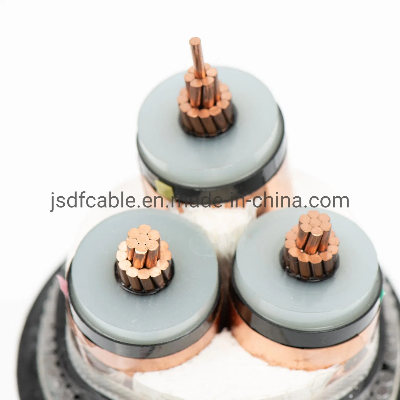

Construction and Material1) ConductorConductors are normally class

2 of compacted cicular or circular standard conductors of copper or

aluminium. 2) Conductor ScreenAll cable of rated voltage above

1.8/3kV are supplied with conductor screening which is

non-mentallic and consists of either semi-conducting tape or

a layer of extruded semi-conducting compound,or

a combination of the two.3) InsulationInsulation is a

layer of extruded cross-linked

polyethylene(XLPE).4) Insulation Screen For cable at rated

voltage above 1.8/3kV ,insulation screening consists of a

non-metallic semi-conducting part in combination with a metallic

layer and consists of either semi-conducting tape or a layer of

extruded semi-conducting compound.. The extruded insulation screen

is normally free strippable(easy removable) type but can be

provided with bonded one upon request. The metallic part is

normally applied on the individual cores for rated voltage above

1.8/3kV and on the core assembly for rated voltage

1.8/3kV and consists of plain annealed copper tape. or copper

tape screen a layer of copper wire,a lead alloy or corrugated

aluminum sheath can be provided upon request. 5) Inner

Covering or Separation Sheath(for armored cables)A layer of PVC

inner coveing is applied under the armor ,if there is no

screen.When the metallic screening and the armor are of

different metals, an extruded separation sheath of PVC is provided

in order to separate the different metals.6) Metallic ArmorThe

armor, if required, consists of single layer of round wires or

double tapes of galvanized steel or aluminum or other non-magnetic

metals. Single core cables are normally armored with aluminum(other

non-magnetic metals), because non-magnetic armor is essential

for single core cable for use on A.C circuit .7) Outer SheathAll

cable are normally provided with an extruded PVC out sheath, black

colored(class ST2). Other materials can be available upon

request,as PE , polyethylene,high flame or fire retardant PVC and

etc.8) Core Identification The multiple conductors are

identified as according IEC60502 . Cable

Marking(Customized) The following information are indicated on

the surface of the outer sheath. However, the marking can also be

customized. ----voltage rating, area for cable----manufacturer's

name----year of manufacturer----lengther for cable----etc

Application: It is used to transmit and

distribute power in power transmission and distribution systems of

35kV or lower. It is generally applied to the fields including

power, construction, mines, metallurgy, petrochemical industry and

communication in complete replace of oil immersed paper insulated

power cable and in partial replace of PVC insulated power cable.

Power cables for power networks, underground, outdoors and in cable

ducting.Standard: BS6622, BS EN/IEC 60228,IEC60502.2Conductor:

Class 2 stranded plain copper conductor to BS EN 60228:2005

(previously BS6360)Conductor screen: Semiconducting

materialInsulation: XLPE (Cross-Linked Polyethylene) Type GP8

to BS7655Insulation Screen: Semi-conducting materialMetallic

Screen: Individual and overall copper tape screen to

BS6622Separator: Binding tapeBedding: PVC (Polyvinyl

Chloride) Type TM1 to BS7655Armoring: Single Core: Aluminium

Wire Armoured (AWA)MultiCore: Steel Wire Armoured (SWA)Sheath: PVC

(Polyvinyl Chloride) Type TM1 to BS7655Colour: Red or Black2. Using

features :Medium Voltage Power Cable Underground 11kv 15kv

33kv XLPE Power Cable1. Rated voltage: Uo/U:3.6/6kV, 6/10kV(11kV),

12/20kV(24kV), 19/33kV, 26/35kV(35kV).2. No. of core: Single-core

or three cores.3. The highest allowed operating temperature of

conductor for long-term working is 90oC. In short-circuit (Max.

long-term is no more than 5 seconds). The highest temperature for a

conductor is no more than 250ºC.4. D.C. resistance of the conductor

complies with the stipulations of 3.6/6kV, 6/10kV(11kV),

12/20kV(24kV), 19/33kV, 26/35kV(35kV).5. The environment

temperature should be no lower than 0oC when lay. Otherwise, it

should be preheated.6. The cable is laid without a horizontal drop

limit.7. Working Frequency Voltage Test: 3.5Uo/5min without

puncture.8. Partial Discharge Test: The discharge volume should be

no more than 10pC under 1.73Uo for the cable.9. Minimum Bending

Radius: Single core - Fixed: 15 x overall diameter;3 core - Fixed:

12 x overall diameter(Single core 12 x overall diameter and 3 core

10 x overall diameter where bands are positioned adjacent to joint

or terminations provided that the bending is carefully controlled

by the use of a former)Note: The single-core armored cables are

used for the D.C. system

Related products about 10kv Mv Underground Three Core Copper Conductor XLPE Insulated and PVC Sheathed Power Cable

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup