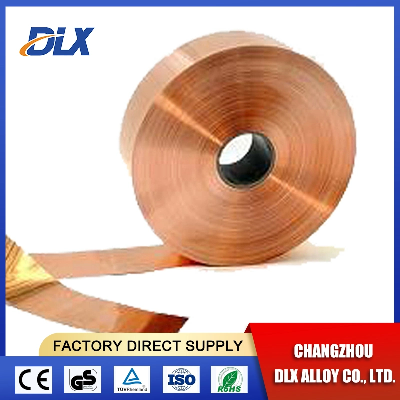

C17200 C17500 Beryllium Copper Strip/sheet/ plate in Coil

Product Description Characteristic of

C17200 CuBe2 Beryllium copper strip• High Strength• Good

Formability• Good corrosion resistance• Easy welding and soldering•

Fatigue ResistantDensity (g/cm3): 8.36Density before age hardening

(g/cm3): 8.25Elastic Modulus (kg/mm2 (103)): 13.40Thermal Expansion

Coefficient (20 °C to 200 °C m/m/°C): 17 x 10-6Thermal Conductivity

(cal/(cm-s-°C)): 0.25Melting Range (°C): 870-980 °CNote:1). the

units are based upon Metric.2). the typical physical properties

apply to age hardened products.Applications:1). Electrical

Industry: Electrical Switch and Relay Blades2). Fuse Clips, Switch

Parts, Relay parts, Connectors, Spring Connectors3). Contact

Bridges, Belleville Washers, Navigational Instruments4). Clips

Fasteners: Washers, Fasteners, Lock Washers5). Retaining Rings,

Roll Pins, Screws, Bolts Industrial: Pumps, Springs,6).

Electrochemical, Shafts, Non Sparking Safety Tools, Flexible Metal

Hose,7). Housings for Instruments, Bearings, Bushings, Valve Seats,

Valve Stems,8). Diaphragms, Springs, Welding Equipment, Rolling

Mill Parts,9). Spline Shafts, Pump Parts, Valves, Bourdon Tubes,

Wear Plates on Heavy Equipment. More Products:More range of

copper and copper alloys, in full series of shapes: Sheet, Rod,

Pipe, Strips and Wire list as below:C17000/170 (CuBe1.7, 2.1245,

Alloy165)C17200/172 (CuBe2, 2.1247, Alloy25)C17300/173 (CuBe2Pb,

2.1248, AlloyM25)C17500/175 (CuCo2Be, 2.1285, Alloy10)C17510/1751

(CuNi2Be, 2.0850, Alloy3)CuCoNiBe (CuCo1Ni1Be, 2.1285,

CW103C)C15000,/150, C18000/180, C18150/181, C18200/182CuZr,

CuNi2CrSi, CuCr1Zr, CuCr Product ParametersMechanical

properties Product Name 0.08-2mm Thickness Alloy 25 Beryllium

Copper strips Material Beryllium Copper Alloys Composition Be

1.86% Co+Ni 0.265% Fe

0.06% Co+Ni+Fe 0.325%

Cu Balance Shape Roll//Strips/coils UNS/CDA UNS: C17200, CDA:

172 ASTM B194 AMS 4530, 4532 RWMA Class 4 Temper A(TB00),

1/4H(TD01), 1/2H(TD02), H(TD04) TemperTensile StrengthYield

StengthElongation A50HardnessBendabilityBendability

(Rm,Mpa)Rp0.2,Mpa

%HVGWBW0410-540-≥3590-160001/4H510-620-≥10145-220211/2H590-695-≥5180-24032H685-835-≥2210-27062Detailed

Photos Certifications Company

ProfileOur company Principle is " Quality first, Customer

first".CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has

got Iso9001 International Quality Management System Certificate and

SGS Certificate. Our factory is professional in researching and

producing special alloy material. From melting, drawing, heat

treatment, finishing and testing .We offer nickel-based,

copper-based, and iron-based alloys, including super alloy, welding

materials, anti-corrosion alloy, precision alloy, FeCrAl alloy,

NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire,

strip, ribbon, bar, tube, plate.1, We're able to design and develop

the product what our customers require and meet their requirements

through providing the appropriate engineering drawings or

samples.2, We can provide the products within a week after

payment.3, Wecan provide sample of the products customer need.4, We

always insist on "Quality first, Customer first" as our business

philosophy.Packaging & Shipping FAQQuestion: Are you a trading

company or manufacturer?Answer: We're manufacturer.Question2:

Could you help to design the product?Answer: Yes, we have

excellent R&D team, OEM/ODM orders are all welcome.

Question: Could you supply samples?Answer: Yes, wecould supply

samples according to your requirement.Question: could we visit your

factory?Answer: Sure, factory visit is warmly welcome./* January

22, 2024 19:08:37 */!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about C17200 C17500 Beryllium Copper Strip/Sheet/ Plate in Coil

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup