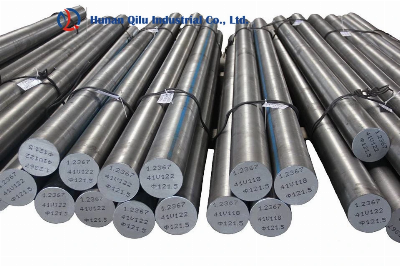

AISI 1045 C45 080M40 Forging Parts Steel Shaft Round Bars1: 1045

steel introductionSteel C45 Round Bar is an unalloyed medium

carbon steel, which is also a general carbon engineering

steel. C45 is a medium strength steel with good machinability

and excellent tensile properties. C45 round steel is generally

supplied in the black hot rolled or occasionally in the normalised

condition, with a typical tensile strength range 570

- 700 Mpa and Brinell hardness range 170 - 210 in either

condition. It does not however respond satisfactorily to nitriding

due to a lack of suitable alloying elements. . 2: 1045 Steel

equivalentCountryJapanBritishAustraliaUSAStandardJIS

G4051EN10083-2AS 1442ASTM A29GradeS45CC45/1.119110451045 3:

1045 steel chemical

compositionGradeCSiMnPSCrMoNi10450.43-0.50.40.6-0.90.040.05///1.11910.42-0.50.40.5-0.80.030.035///S45C0.42-0.480.15-0.350.6-0.90.030.03///

4: 1045 steel mechanical properties The

mechanical properties mainly include tensile strength, yield

strength, elongation, area or reduction, hardness, impact value,

non-metalic inclusion etc. Different heat treatment, the mechanical

properties will be different, such as normalized, tempered, QT. If

you want to know the properties, kindly contact the salesman. 5:

1045 steel overviewsSizeRoundDia

6-1200mmPlate/Flat/BlockThickness6mm-500mmWidth20mm-1000mmHeat

treatmentNormalized ; Annealed ; Quenched

; TemperedSurface conditionBlack; Peeled; Polished; Machined;

Grinded; Turned; MilledDelivery conditionForged; Hot rolled; Cold

drawnTestTensile strength, Yield strength, elongation, area of

reduction, impact value, hardness, grain size, ultrasonic test, US

inspection, magnetic particle testing, etc. Payment

termsT/T;L/C;/Money gram/ PaypalTrade termsFOB; CIF; C&F;

etc..Delivery time30-45 daysApplication1045 alloy steels are used

for axles, bolts, forged connecting rods, crankshafts, torsion

bars, light gears, guide rods, screws, forgings, wheel tyres,

shafts, sickles, axes, knives, wood working drills, hammers, etc.6:

Delivery conditionFor hot forged bar, usually the

delivery condition is hot forged, annealed/QT, rough turned/Black

surface. For hot rolled bar, usually the delivery condition is hot

rolled, annealed/QT, Black surface. For Cold Drawn bar, usually the

delivery condtion is cold drawn, annealed/QT, peeled/black surface

For hot rolled plate, usually the delivery condition is hot rolled,

annealed, milled/black surface For hot forged plate, usually the

delivery condition is hot forged, normalized/annealed, milled/black

surface. Hunan Qilu Industrial Co., Ltd has the capacity to forge

round steel, steel flat, square steel, module, shaft and roller,

etc. The main specifications of the products include Φ80-1000mm

forging materials and 80-1200mm square billets and which the

maximum piece weight can reach 50T. Hunan Qilu Industrial Co.,

Ltd were already engaged in exporting steel for 11 years,

could supply a great variety of hot forged, hot

rolled and cold drawn Steels, including

engineering steel, cold work tool steel, hot work tool steel,

plastic mold steel, spring steel, high speed steel, stainless steel

etc., besides Qilu Industrial also has their own heating treatment

shop and machining shop to provide heating and cutting service.

Since 2008 year, Hunan Qilu Industrial has the right to export

all FORGED STEEL behalf of Qilu Speical Steel Co.,ltd

which is specialized in smelting and forging of special steel since

1965 year, now Qilu special steel is one of the biggest

manufacturer of forged product in China.The forged products are

used in Automotive, Aerospace, Power Generation, Oil

& Gas, Transportation and Industrial. We already set up

the warehouse in Wuxi and Dongguan city, more than 20000 tons

ex-stock could be supplied with kinds of size. Qilu Industrial is

the professional one-stop steel manufacturer, stockist and exporter

in China, our customers spread all over the world, include West

Europe, North America, South America, Asia, Middle Asia, Africa,

Australia, etc. The company owns advanced special steel smelting

facilities and forging processing equipments, the main steel-making

equipment include 2 sets of 50t ultra-high power electric arc

furnaces,2 sets of 60t LF refining furnaces,1 set of 60t vacuum

degassing refining furnace and 4 sets of 1-20t electroslag

re-melting furnaces. The main forging equipments mainly include:3

sets of 5t electro-hydraulic hammers, 1 set of high-speed

forging units of 800t,1600t,2000t and 4500t respectively. Hunan

Qilu Industrial CO., LTDWeb:

qilusteel.en.made-in-china.com /* January

22, 2024 19:08:37 */!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about AISI 1045 C45 080m40 Forging Parts Steel Shaft Round Bars

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup