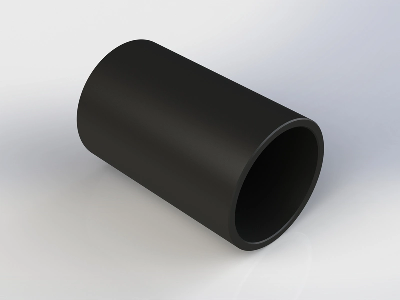

INDRON® elastic-plastic polymer alloy composite(referred as

elastic-plastic for short) has the advantages of low friction and

light wear, effectively reducing the wear of friction pairs.

INDRON® bearings can be widely used with water power and hydraulic

machinery such as hydro-electric installations, clean energy

generation, ships and offshore installations, which uses water as

lubricant instead of mineral oils and thus avoid leakage and

release of mineral oils.The surface hardness of INDRON® hRBR

is relatively low. Giving way to the burial of abrasive grains and

transferring them from the friction pair to the water tank to

discharge them can guarantee the most wear-resistant grade in

INDRON® elastoplastic alloy. The performance remains excellent

in the medium of high sediment content.What bearing materials are

more suitable as the materials used for water pump guide bearings,

Babbitt alloy, rubber, ceramics or new polymer materials? It is

advisable to take account of the lubrication requirements, use

environment and maintenance cycle of the equipment.COMMON GUIDE

BEARING MATERIALSBearing typeINDRON bearingAR bearingCeramic

bearingRubber bearingBabbitt alloy bearingCharacteristicsThe

performance is close thordon, which can use more equipment assembly

methods. In addition to traditional installations by freezing and

pressurizing. It can also be installed by coating reactive thermal

polymerization Dx and cold sticking.Good wear resistance and impact

resistance. The bearing hardness is high; the shaft sleeve is easy

to wear; the temperature difference changes greatly; there will be

the risk of shelling; the price is high.Wear-resistant,

heat-resistant, corrosion-resistant, lubricated by pump circulating

water, capable of dry grinding for a short time, high requirement

on accuracy in processing and assembly, fragile and the most

expensive.It has a long history and mature manufacturing process,

featured by wear resistance, anti-seismic, impact resistance,

convenient assembly/disassembly and low price (only 20% of ceramic

bearings price)Wear resistance and impact resistance require a set

of more complicated sealing and lubricating devices and

mechanisms.Lubricating requirementsClean water can be used for

lubrication or 150s dry start according to the material grades.Dry

start more than 180S without clean water lubrication.It can be

lubricated by pumping medium without special clean water

lubrication.Clean industrial waterGrease lubrication requires a

grease supply lubrication system.Working temperature≤70ºC≥273ºCThe

bearing itself can withstand the temperature of

1,400ºC≤50ºC≤65ºCShort time up to 80ºCApplication siteFor pumping

stations short of clean water or pumping stations requiring

short-term dry friction, hRBR grade is suitable for water quality

with moderate sediment content.Pumping stations without clean water

or pumping stations requiring dry friction of more than

180S.Pumping stations without clean water or pumping stations

requiring short-term dry friction.Extensive application in any

pumping stations with clean water sources.The liquid of the pump

itself cannot be used for bearing lubrication in the pumping

station.Bearing typeINDRON bearingAR bearingCeramic bearingRubber

bearingBabbitt alloy bearing/* January 22, 2024 19:08:37

*/!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Elastomeric Polymer Used in Pump Bearing, Shaft Seals

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup