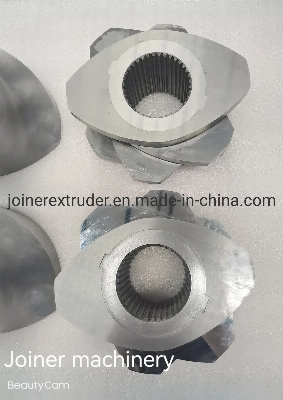

320MC Corrosion Resistace Extruder Screw Segments for Petrochemical

Industry Joiner is state-of-the art and spans over 20,000

square meters. The factory houses more than 150 sets of different

domestic and foreign high precision production equipment, with the

degree of numerical control up to 95%. 1. Details of

screw elements Screw DesignDouble-ScrewHardness58-60HRCHeat

treatmentVaccum heat treatmentSurface

TreatmentPolishingFeatureSingle keylotStandard DIN, GB,

etc.TechnicalsCNC machining 2. Process of making 3.

Raw material guaranteeThe company has been cooperating with

domestic and foreign first-line brand material suppliers for a long

time, and has a strict quality control and performs regular audits

and inspection of the factory (elemental analysis, metallographic

analysis, ultrasonic flaw detection, etc.) to ensure a 100%

qualified status. 4. Heat treatment As we all know, heat

treatment is very important in the screw production process. In

order to ensure the quality of products, Joiner has purchased

professional heat treatment equipment to produce, so that we can

control the construction process by ourselves. 5. Packing

Details:According to your order quantities and products sizes to

choose wooden boxes or cartons to pack:Rust-proof oil

processing,Oiled paper packages,Bubble wrap package,Special foam

packaging,Packing,Sealing. 6. Why choose us?a. Total solution

of highly wear-resistance and corrosion-resistance problems;b.

Expert of engineering design and consulting,c. Advanced

manufacturing capabilities and technology,d. Lean production

managemente. Top quality products with high cost

performance 7. Products photos: 8. Example

spare parts we produce for Petrochemical

IndustryBarrel:Shafts:/* January 22, 2024 19:08:37

*/!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about 320mc Pelletizer Screw Elements for Petrochemical Industry

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup