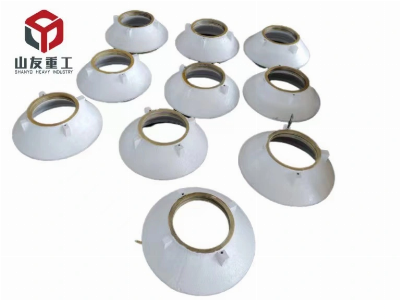

Product Description Our company has long-term stock of

accessories and vulnerable parts,which can be interchanged with

original accessories. Simply provide the original part number to

produce, and the materials and dimensions meet the original

quality. This allows users to use and purchase with confidence

before and after purchase, ensuring production.Manufacturing

Process: a. drawing inspection > b. wood type making > c.

casting > d. tempering > e. roughing maching > f.

tempering > g. finishing maching > h. CNC maching > i.

coloring flaw testing > j. ultrasonic flaw testing > k. three

coordinate detection > l. coloring flaw testing > hardness

testingTechnical SpecificationModelFeed opening (mm) Max feed

size(mm)C.S.S (mm)Capacity (t/h)Power (kw)Overall dimensions

ModelPart NumberDescriptionSymons

3ft 7320-3201Main shaft sleeveSymons 3ft2747-5951Main shaft

sleeveSymons 4ft7320-4200Main shaft sleeveSymons 4ft7320-4201Main

shaft sleeveSymons 4ft7320-4331Main shaft sleeveSymons 4

1/4ft7320-4202Main shaft sleeveSymons 4 1/4ft7320-4331Main shaft

sleeveSymons 5 1/2ft2748-2476 Main shaft sleeveSymons 5

1/2ft5013-6801Main shaft sleeveSymons 5 1/2ft7320-6600Main shaft

sleeveSymons 7ft2748-4501Main shaft sleeveSymons 7ft7320-8350Main

shaft sleeveSymons 7ft7320-8011Main shaft sleeve dPackaging

& Shipping Company ProfileShenyang Shanyo Heavy Industry

Machinery Manufacturing Co., Ltd., founded in 1996, is located in

Shenyang, Liaoning Province, the old heavy industry base in

northeast China. Shenyang Shanyo Heavy Industry Machinery

Manufacturing Co., Ltd., is the first batch of manufacturers to

produce and manufacture mining machinery and equipment.Since the

establishment of the company, we have always adhered to the

business philosophy of "credibility first, customer first". In

terms of quality, we strictly control the quality. We adhere to the

attitude of "quality is the root of the manufacturer, and product

difference lies in the details" in all aspects of material

procurement, machining production, assembly equipment and

commissioning. We have produced more than 1000 sets of mining

equipment. With our reliable quality assurance and excellent

after-sales service, we have won the unanimous praise of the

majority of users. Our company is located at No. 6, Hangzhou West

Road, Shenbei New District, Shenyang City, Liaoning Province,

covering an area of more than 50 mu, with a manufacturing workshop

of 35000 square meters, nearly 200 employees, 16 professional and

technical personnel, and an annual output value of about 50

million.Our company has 5 meters, 3.4 meters, 3.2 meters, 2.5

meters and other vertical lathes. 160, 125, 80, 60, 20 and other

horizontal lathes. More than 40 sets of floor boring machines such

as 160, 90 and 60 and various processing equipment such as 100, 80

and 50 radial drills. In terms of production and processing,

through reasonable arrangement, both high quality and high

efficiency are guaranteed. The vulnerable parts, spare parts and

product parts of all equipment are independently processed and

produced by our factory.Our company's products mainly include

mining equipment such as cone crushers, rotary crushers, jaw

crushers, ball mills, etc. The equipment specifications range from

large to small, with complete models. At present, there are many

categories of cone crushers in our company's main core products. In

addition to the classic spring crushers, our company's subsequent

main HP/MC multi cylinder cone crushers and CH-CS/SC single

cylinder crushers are all manufactured according to the imported

original drawing 1:1, which can replace the original imported

crushers. Due to their high cost-effectiveness and timely

after-sales service, they have received recognition and support

from many customers. Our company also has long-term stock of

accessories and vulnerable parts, can be interchanged with

original accessories. Simply provide the original part number to

produce, and the materials and dimensions meet the original

quality. This allows users to use and purchase with confidence

before and after purchase, ensuring production.Installation

Instructions 01. Installation of Underframe1) The equipment is

placed on the basis of construction. 2) Equipment placement: The

equipment needs to be pre embedded with anchor bolts according to

the foundation drawing (according to user requirements, anchor

bolts can also be omitted and a pre embedded iron scheme can be

used): a. Perform the second grouting according to the position of

the foundation bolts on the foundation drawing. b. After the

secondary grouting layer hardens, install the base frame. 3) When

installing the underframe, strict levelness should be maintained.

Before installation, the corresponding positions of the underframe

damping pads must be polished flat, and the foundation levelness

should be checked with a level gauge. 4) Maintaining the levelness

of the base can ensure the dynamic balance of the equipment, thus

effectively ensurin

Related products about Shanyo Symons Cone Crusher Parts Symons Main Shaft Sleeve Stone Crusher Mining Machine for Sale

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup