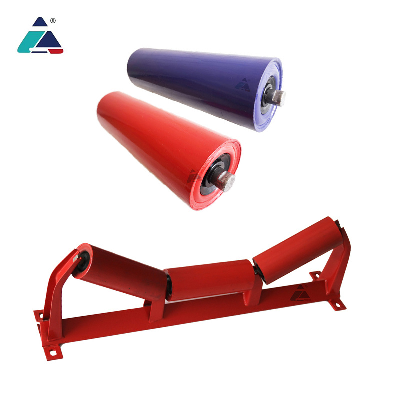

Product DescriptionConveyor accessories Roller support supports the

trough roller TD2A Type Each group can support three

rollersProduct Description35° Related parameters of groove

idlers Belt WidthB

Main size

DL AECHH1H2PQdWeight/kg40063.5160600660464185112242170130M129.61764609511825411.489 -----

5006320074080057020011927270130M1212.5765672101222814.989559220135.30015.865076 890950698225122310170130M1216.689 250691235135.532917.1 108 5842654634621.38089 1090115086224535.5366170130M1222.110831585527014638526.7138413055940833.21000108 29013501038300159437220170M1638.01333801023325173.46145.5591020370[904957.11200108 1540160026233517650260200M1650.51334651248360190.552159.2159244390207.555672.4400108 174018101433350184546280220M1656.2133 530141938098.557365.61591415410215.60287.8160013 9902060[603430205619300240M1685.31596001598460220646100.8194 ------1800132670219022601788455215669300240M1698.31591784485230696114.8194 1784525255739152.3200013375024202490999460215715300240M16107.1591995500230742125.4194995540255785165.9220013380027202800 159 194 2400[5990030203110 194 219 Factory

display Laser cutting machine. The computer controls

theprecise data, and the cutting surface is smoother. CNC

bending machine can precisely control the bendingAngle and bending

radius Manual operation of welding points by skilled workers

ismore secureInstallation instructionsThe installation steps of the

conveyor support are as follows:1. Determine the installation

position of the support: according to the needs of the conveyor,

determine the installation position of the support, and consider

the length, height, weight and other factors of the conveyor.2.

Obtain installation materials: Obtain required materials, such as

bolts, nuts, Angle steel, and channel steel.3. Install the Angle

steel bracket: Cut and weld the Angle steel according to the

requirements of the device installation drawings, and then fix it

to the foundation.4. Install the channel beam: Install the channel

beam above the Angle steel support and fix it to the Angle steel

support.5. Install the column: Fix the column on the channel steel

beam, pay attention to the position and Angle of the column, and

ensure that the column is perpendicular to the channel steel

beam.6. Install adjusting bolts: Install adjusting bolts on the

Angle steel support to adjust the height and levelness of the

conveyor.7. Install the support rod: At the connection of the

support and the conveyor, install the support rod to support the

conveyor and prevent the deformation and shaking of the conveyor.8.

Adjust the position of the support: After the installation is

complete, fine-tune the position of the support according to the

need to make the conveyor run smoothly.When installing a conveyor

support, perform operations according to the installation drawings

and ensure installation quality to ensure the normal and safe

running of the conveyor. /* January 22, 2024 19:08:37

*/!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Factory Customizes Mining Conveyor System Components and Various Consumables.

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup