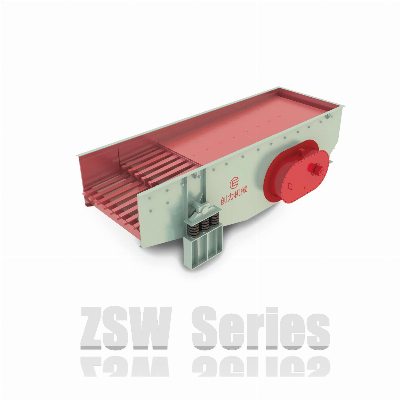

Product DescriptionZSW Series Linear Vibrating Feeding

Machine ln the production process, the linear vibration

feeder can evenly feed block and granular materials from the

storage bin and roughly screen the materials. lt has the

characteristics of vibration balance,reliable operation, long

service life, and large output. The bearing pedestal of this model

is processed by a large CNC boring and milling machine, which

ensures the concentricity of the bearing pedestals at both ends and

the machining accuracy of each part. The bearing is lubricated by

Gear oil, which is better than the traditional grease cooling

lubrication, and extends the service life ofthe bearing. This

equipment is widely used in crushing and screening combined

equipment in industries such as metallurgy, mineralprocessing,

mineral processing, building materials, and chemical engineering.1.

Linear motion trajectory vibration balance, reliable operation2.

Special grid design prevents the control of the feeding amountand

does not need to start the motor frequently3. Adopting frequency

modulation and speed regulation, it is convenient tocontrol the

feeding amount and does not need to start the

motor frequently4. The equipment works in a resonance

state, with stable amplitude, reliable operation, and strong

adaptability to various materials5. Low noise, beneficial for

improving the working environment6. Simple and compact structure,

easy installation and maintenance,low operation cost Product

ParametersTypeMax.FeedingEective Working PlaneCapacitySlot

DipPowerOverall

Dimensions(mm)(mm)(t/h)(°)(KW)(mm)ZSW15608001500*6000400-

8000-1045KW6000*2212*1820ZSW176010001700*6000600 -

10000-1055KW6000*2412*1820ZSW196012001900*6000800-

14000-1075KW6000*2612*1820Detailed PhotosClassic ProjectMore Our

ProductsCompany ProfileCHUANGLI is one of most famous brands in

China since started in 1987, is a hightech manufacturing company

committing to R&D, production and marketing of crushers, sand

making machines, vibrating screens, feeders. The main business

covers mines, quarries, aggregates, cement, chemical, oil and gas

refining, power utilities, waste to energy and construction

projects.The technical support team intervenes as soon as possible.

If there is a need for spare parts, the necessary spare parts are

provided immediately and the malfunction is eliminated. Thus, the

crusher plant can produce again. This prevents companies from

increasing their costs. Also;• All CHUANGLI Group spare parts are

original and guaranteed• Rich spare parts options are available•

Prevents performance degradation in crusher plants• Reduces the

maintenance costs of user companiesWe are committed to providing

high quality of products, along with top quality of service. Let

CHUANGLI be your business partner.GLOBAL COOPERATION Strong

partners ensure that CHUANGLI can continuously provide high quality

service for our customers.CHUANGLI has been exported products to

the different countries and regions in America, Europe, Asia,

Africa and Oceania, which is providing practical products and high

quality services to customers.FAQQ: Why we believe in CHUANGLI

Group company?A:1. More than 36 years experience. 2.

CHUANGLI is the leading professional supplier of solution,

equipments and service for crushing and grinding industry.

3. All products achieved ISO9001:2000 quality management

certificate and EU CE certificate. Q: Delivery timeA: The lead

time is 10-30 days, Delivery time will vary depending on the type

of the machine, shipping method selected and

part availability. Q: Payment termsA: Accepted Payment

Type: T/T, L/C, Western Union, Cash After sign the

contract, pay the 10%-30% deposit of total purchase price and pay

the full payment before delivery. Q: what will you do if the

machine is broken down?A: The Products warranty is one year. We

will provide the technical advice and find the solution immediately

for you when the machine is in trouble.

For those wear parts, we guarantee the high quality parts for

long-term supply. Q: What should i do if I want to get a best

quotation?A: If you want a suitable type for you ,please let us

know your material and capacity.Contact usIn order to

recommend suitable design for you, please kindly tell

me: ♥ What is your raw material to process? is it

soft stone (like limestone, dolomite) or hard stone (like granite,

basalt, river stone, etc)? ♥ What is the maximum feed

size of your raw material? like 10-50mm ♥ What are output

sizes you want? like 5-10mm or 150-2000 meshes ♥ What is

per hour capacity you want? like 5tph or 200tph/* January

22, 2024 19:08:37 */!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Mining Conveyor ZSW Linear Vibrating Feeding Machine of Mining Machinery

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup