Company Profile The origin of CPM can be traced back to

California's Napa Valley, where, in 1883, the Toulouse & Delorieux

Co. Manufactured presses, crushers and stemmers for winemakers. In

1931, the company created the first pellet mill, the 30 HP Flat Bed

with stationary flat die, and we became California Pellet Mill

(CPM).In the years that followed, we created more pellet mill

models with additional features. In the 1980s, we greatly expanded

our product offerings through the creation of Roskamp Champion with

the acquisition of the Roskamp Roller Mill Company and Champion

Hammermills.Wolverine Proctor, part of the CPM Group in the United

States, founded in 1812, the company has a history of more than 200

years, starting from the production of textile machinery, after

more than two centuries of industry accumulation, now has been the

leader in the field of drying.Our dryers are sold to more than 100

countries around the world, and more than 10, 000 drying equipment

are in operation around the world, and continue to serve food,

chemical, textile chemical fiber,tobacco and other fields.We have

global team and can provide excellent drying solutions and services

for our customers.Wolverine Proctor products first entered China in

1912 and have accompanied the development and growth of various

industries in China for more than 100 years.Wolverine Proctor's

headquarters and production center are located in Lexington, North

Carolina, USA, as well as the North American Business and

Experiment Center in Horsham, Pennsylvania, USA, the European

Business and Experiment Center in Glasgow, Scotland, and the Asia

Pacific Business and Experiment Center in Wuxi, China.Wolverine

Proctor has the customized design technology reserves accumulated

by the century, extremely rich industry technology accumulation,

its huge application and design and service team with the common

development of food, chemical, textile chemical fiber and tobacco

fields in different regions of the world, and provides customized

large-scale drying, baking and cooling equipment solutions for

global customers. Our Advantages

FIBERS We've been generating profits for our fiber

customers for more than a century.Your fiber business is

complicated, and you know the ins and outs of it all. You need a

partner who's just as committed and experienced in the processing

industry as you are. CPM Wolverine Proctor has been working with

fiber customers for over 100 years, refining our industry-leading

equipment to dry, cure, and laminate at the lowest possible

operating costs. We're experts who know exactly what you need to

get the most out of your operation. Click an image below to learn

more about your fibers application. Uniform curing for your

bonded batting.To produce the quality bonded batting your customers

want, you need quality equipment that you can rely on. At CPM

Wolverine Proctor, we offer a range of bonded batting equipment so

you get the right piece of equipment for your unique operation. Our

systems bring unsurpassed efficiency to any bonded batt process.

From resin spraying to drying, our machinery sets the standard in

fabric production. Effective chemical and glass fiber

drying.Built for efficiency, CPM Wolverine Proctor equipment will

help you optimize your fiberglass operations and maximize your

processing time. Our machines are designed with simplified controls

while retaining the rugged performance our reputation is built on.

The effective nozzle systems, temperature controls, and auxiliary

equipment are designed to evenly distribute heated air across your

glass fibers and meet the strict requirements of your individual

plant processing operations. The right equipment for a wide

range of yarn.The fiber industry produces many types of yarn, each

with its own unique drying requirements. At CPM Wolverine Proctor,

we've designed our equipment to meet the needs of them all. Our

machines are engineered for unequalled final product uniformity and

are proven to work as hard as you do. From angora to synthetic, CPM

Wolverine Proctor is your go-to source for consistent, high-quality

yarn processing results. Knitting together our proven

equipment with our industry know-how.Moisture can accumulate to

unwanted levels during the fabric manufacturing process, and that's

where CPM Wolverine Proctor can help. Our equipment is engineered

for minimum energy consumption, outstanding flexibility, and

unmatched performance. Our long history of working with users and

mill men gives us in-depth knowledge of the entire knit or woven

fabrics process and exceptional insight to help you meet your

specific requirements. Providing a variety of solutions for

your unique fibers operation.CPM Wolverine Proctor provides a wide

range of equipment for acrylic and acetate fiber staple and tow

fabric production. Our spectrum of heavy-duty dryers and auxiliary

equipment is ruggedly built to process your materials with

world-class efficiency. Regardless of the quantity of material

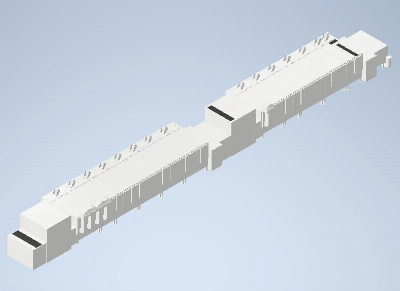

Related products about Conveyor Belt Steamed Heated Scf Fiber Dryer Machine

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup