Pneumatic conveying systemSDCAD - A pneumatic conveying

system transfers dry bulk materials or powders through an enclosed

conveying pipeline using pressure differential and gas flow

(usually air), generated by an air movement device such as a fan,

roots blower or compressor. Pneumatic conveying systems use a

series of pipelines that move products by pumping air.These

products typically consist of powders or granules. These systems

function by moving materials through enclosed, airtight pipelines

through a combination of airflow or another type of gas and

pressure.The forms :Pneumatic conveying are the dilute phase and

dense phase.The Type: Pneumatic conveying are pressure and

vacuumApplication: Cement, fly ash, starch, sugar, salt, sand,

plastic pellets, oats, polymers, lime, soda ash, plastic resin,

plastic powder, dry milk, and feeds Pneumatic Conveying

System Full Process Solution Provider SDCAD Why choose us?Our

pneumatic conveying is designed to match with flow requirement of

cement plant Cement silo, and we have20+ years of experience in

cement equipment manufacture and EPC project. The pnenumatic

conveying produced by SDCAD is easy to install, safe and reliable,

and win a good reputation on the market. We own a professional R &

D, design, production, installation team, and provide users with

one-stop service, including the process design, automatic control

and steel plate warehouse, transportation, cleaning, dust removal

equipment manufacturing, installation, commissioning and personnel

training. We can provide The positive or negative pressure in a

pneumatic conveying line moves materials safely with little damage

or loss. Pneumatic conveying systems use pipes or ducts to

transport materials on a stream of air.Three coneying

modesA:Suspend flow the material becomesuspend state in the pipe,

this way suit low pressure, this way suit dilute phase

shortdistance. B:Group flow the material become groupstate, this

way suit middle pressure longer distance. C:Bolt flow the material

is cut intobolt by pulse gas valve in the pipe, then go on

depending on the air quiet pressuredifference. It is suitable for

high stress, dense phase, longdistance, and low velocity.PRODUCT

SPECIFICATIONSAdvantages of SDCAD Pneumatic conveying * Due

to the compact nature of the conveying pipe transfer line, a

pneumatic conveying system can be routed around existing equipment,

giving more flexibility than a mechanical conveying system.* Can

run vertically or horizontally over a long distance.* As the system

is enclosed, there is protection against dust emissions to the

atmosphere and also protection of the conveyed material from

external contaminants.* Pneumatic conveying systems can be easier

and more cost effective to maintain than a mechanical conveying

system - fewer moving parts.* The ability to maintain a controlled

atmosphere around the material.* Minimise system wear from abrasive

materials and damage to fragile materials.* Take up less floor

space so are easier to locate.* Can have multiple pick up and

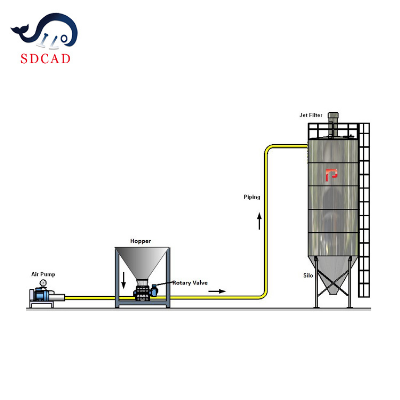

discharge points.PRODUCT CONFIGURATIONPneumatic Conveying DesignAll

pneumatic systems use pipes or ducts to transport materials on a

stream of air. An air mover generates pressure or a vacuum and is

located in the system at the beginning to push materials through

the line or at the end to pull materials through.The basic

components of a pneumatic system are:1. Pressure blower or vacuum

pump2. Rotary airlock valves3. Conveying line4. Diverter valves5.

Filter receiver6. Cyclone separators7. Batching systems8. Hoppers9.

Controls Full Process Solution Provider - SDCAD* A pneumatic

conveying system allows greater versatility than a mechanical

conveying system because it may be compatible with existing

equipment due to the small nature of the conveying pipe's transfer

line.* These systems can cover a large distance running either

horizontally or vertically.* Due to the enclosure of the system,

both the delivered material and dust emission to the atmosphere are

protected from outside contaminants.* Because they have fewer

moving components than mechanical conveying systems, pneumatic

conveying systems can be simpler and more cost-effective to

maintain.* They maintain a capacity to keep the environment around

the substance under control.* They reduce abrasive material wearing

on the system and fragile materials damage.* These systems are

easier to find because they occupy less floor space.* Various

pick-up and discharge points are possible.Product ShowPre-Sales

ServiceAfter-Sales ServiceCustomer consultant 24 hour

online;Engineer team provide design drawing;Skilled staff

responsible for production;Take pictures for all Production

process.Provide installation instruction;Solve any problems

involved;Tell the machinery maintain guidance;Regular monthly sales

tracking.Related Products

Bolted Silo

Container Horizontal Silo

Big b

Related products about Moban Sdcad Powder and Particle Dense-Phase Rotary Valve Model Pneumatic Conveying System

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup