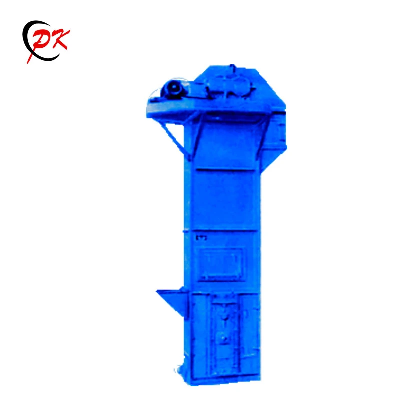

Steel Vertical Conveyor Belt Machinery Vertical Bucket

ElevatorIntroductionTH Ring chain bucket conveyor also named double

chain bucket elevator. Compared with TD belt bucket conveyor, ring

chain conveyor use forging ring chain as their traction component.

It is widely used for bulk material which density less than

1.5t/m3,such as Coal, cement, sand, fertilizer, food, etc.

Advantages and Features 1.Excellent sealing, less

environmental pollution 2.The bucket elevator wheels have bolted

rims easily replaceable fabricated in wear resistant steel.

3.Symmetrical weight distribution to long life of chain and

driveshaft. 4.Energy conservation and less maintenance ensure the

machine a very low cost. 5.Advanced design principle has ensured

the reliability of machine operation. 6.High manufacture accuracy.

The housing case is of good rigidity and beautiful appearance by

the edge folding and intermediate beading. 7.Lifting height up to

60m. 8.Compact installation arrangement. 9.Height can be customized

according to your need Selection

Conditions♦Material to be processed: _____♦Material is corrosive or

not: ____ (Ps. Yes or No)♦Handling capacity (Ps. It means the

total♦Working environment is indoor or outdoor:________material

capacity feeding from the inlet): _____t/h♦Material is liquid or

not:___________(Ps. Yes or No)♦Bulk Density: _____t/m3♦Working

environment temperature: _______ ºC♦Lifting height of the

elevator (distance between♦Upstream equipment (Ps. It means

what kind of inlet and outlet):__________mequipment is used to

feed the material): _____♦Max. granule size of the feeding

material: ____mm♦Downstream equipment (Ps. It means what kind

of♦Percentage of Max. granule in material:_________%equipment is

used to discharge the material): _____♦Material temperature:

_____ºC;♦Working power supply: _____V ______HZ ♦water

content:____% ApplicationHigh quality vertical belt type

bucket elevator/conveyor/lifting machine is used for

transferring the materials in form of powder, granular, small block

non-abrasive, half-abrasive with bulk density less than 1.5t/m3,

such as coal, cement, gravel, sand, fertilizer and grain etc.

Working PrincipleWhile it is energized, the driving device drives

pulley to make the bucket belt doing the circular motion from

bottom to up. The bucket is filled with material and is conveyed to

the head terminal, and then the material is thrown from the outlet

under the action of centrifugal force according to the Parabolic

design.After discharging, the empty bucket is back to the boot by

conveying and be filled again, and then lifted up to do parabolic

motion such repeated cycle.The material is lifted from bottom to

the top to the specified height to reach conveying vertically.

Technical performance and parametersModelTD160TD250TD315TD400Bucket

typeQHZdSdQHZdSdQHZdSdQHZdSdCapacity

(m3/h)91616272036385928504267407668110Bucket

width(mm)160250315400Bucket

volume(L)0.50.94.21.91.32.234.623.63.85.83.15.65.99.4Belt Width

(mm)200300400500ModelTD500TD630Bucket typeQHZdSdQHZdSdCapacity

(m3/h)6311696154_142148238Bucket width(mm)500 Bucket

volume(L)4.8499.314.9_1414.623.5Belt Width (mm)600700Note: the

parameter above is just for reference,it can be customized by

different requirment. About our factory:In the

situation of global economic integration and large

and fierce competition international market, Henan Pingyuan

Mining Machinery Co., Ltd (PK Machinery) takes the goal of

creating a global strategy, and actively

promotes technological and

management innovation, as well

as improves overseas business model, thus cultivates an

highly qualified and inter-disciplinary talent team to

adapt international market changes and overseas business

development. In this case, PK Machinery can constantly enhance

its international competitiveness so that could

participate in international competition and cooperation

at a higher level and broader area as well as more ranges,

meanwhile to lead the national industry realizing leap-forward

development.It is a information explosion century in 21st

century. With the development of high-tech products and its

widely application, the speed of global communication and

integration has been accelerated. As a high-end mining equipment

manufacturer, our company attaches great importance to

technology exchange and strategic cooperation with other

countries. What's more, we actively expend overseas

markets by mature products and perfect service

systems. By the end of 2015, our products have been

successfully exported to over 60 countries and regions, such as the

United States, Canada, Brazil, Chile, Peru, the United Kingdom,

Germany, Italy, Russia, Ukraine, Kazakhstan, Iran, Saudi Arabia,

India, Pakistan, Malaysia, Thailand, South Africa, Ethiopia,

Australia,etc.Open-door to the outside world is a platform for

rapid development. Under the background of economic globalization,

PK Machinery is committed to provide world-class products

and superior service for our customers, and s

Related products about Vertical Belt Bucket Elevator

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup