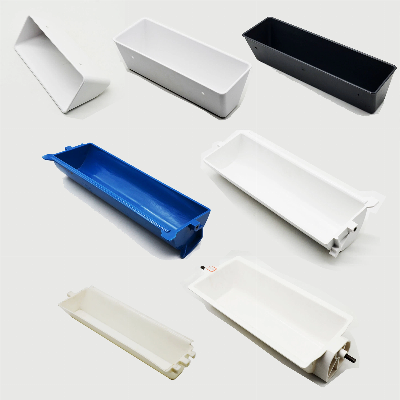

Plastic bucket, lifting hopper, grain lifting bucket (special

accessories for grain elevator)-is a kind of bucket used for grain

lifting and special material lifting. The lifting bucket models

are: SB1109, SB1311, SB1612, SB1812, SB2314, SB2814, SB3518 and

other models, special ones can also be customized within a certain

range. The corresponding bucket belt widths matched by the lifting

bucket are: 100mm, 125mm, 150mm, 180mm, 200mm, 250mm, 300mm, 400mm,

etc. Qingdao Yida industry and Trade Co., Ltd. is a

professional manufacturer of injection molding plastic products and

mouldsprocessing. Founded in 1999,The products range covers

Construction, Home Appliances, Foods, Machinery, Vehicles &

Accessories, Daily Consumer Goods, Sports & Fitness, Electronic

Components & Accessories, Tools, Fishery, Packaging & Printing

etc. Rapid toolingFast and cost-effective process to create

aluminum or steel injection molds for quick turn injection molding.

Ideal for rapid prototyping needs or validating product concept for

production.OvermoldingOvermolding is a unique injection molding

process that combines two or more components together. It is the

best practice for the plastic manufacturing of multi-color and

multi-layers products.Insert moldingInsert molding is a custom

injection molding process that encapsulates components in a plastic

part. It is most commonly used forprototype injection molding

designs with threads and holes. Liquid Silicone Rubber

injection moldingLiquid silicone rubber (LSR) is a flexible

prototype injection molding process that produces elastic, durable

parts. Get customprototypes and production parts from 15

days. Mould Design ProcessStep 1: Analyze the product

drawingsStep 2:Create the Design for Manufacturability (DFM)

reportStep 3: Make the mould flow analysisStep 4: Design tooling

drawingsStep 5: Mould makingOnce the mould making is finished,

we'll make several pieces of pre-production samples for test, if

the dimensions are correct,then we will send the samples to

customers for final confirmation. If the test failed, we will

modify the mould or adjust the molding parameter to make new

samples, and test it again. Once the samples are approval by

customers, we will purchase the raw material and making quality

inspection. Then mixing material, molding and trimming, we will

make many times of inspection during the production. Finally we

will arrange the assembly and packing. After whole order is ready,

we will send the packing list to customer to arrange the

shipment.Mold MaterialS45C, S50C, P20, 718H, 738H, NAK80, S136,

S136HMold Life Time300K timesProduct MaterialABS+PC, PP, PC, ABS,

PA, HIPS, PVC, PE, PS, POM, Acrylic,SurfaceSmooth, glossy,

textured, matteSize1) According to customers' drawings2) According

to customers' samplesDrawing Formatstep, dwg, igs,

pdfProcessInjection Plastic ModlingPayment TermT/T, L/C, Trade

AssurancePlace of OriginChinaColorCustomizedFAQQ1:Where can I get

product&price information? A1:Send us e-mail , we will

contact you as we receive your mail. Q2: How soon can I get

samples? A2: Depending on your specific project, it usually

takes 10 to 20 days. Q3:How to enjoy the OEM

services?A3:Usually, base on your design drawings or original

samples, we give some technical proposals and a quotation to you,

after your agreement, we produce for you. Q4:Can you make

machining parts based on our samples? A4:Yes, we can make

measurement based on your samples to make drawings for machining

parts making. Q5: Is it possible to know how are my products

going on without visiting your company?A5: We will offer a detailed

production schedule and send weekly reports with digital pictures

and videos which show the machining progress./* January 22, 2024

19:08:37 */!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Factory Directly PP Food Grade Plastic Elevator Buckets Conveyor Buckets

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup