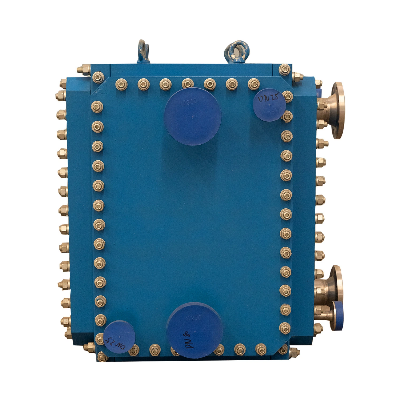

Plate heat exchanger is an ideal equipment for heat exchange

between liquid and steam. The utility model has the advantages

of high heat exchange efficiency, small heat loss, compact and

light structure, small floor area, wide application, long

service life, etc. Under the same pressure loss, the heat

transfer coefficient is 3-5 times higher than that of the tube heat

exchanger, the floor area is one third of the tube heat

exchanger, and the heat recovery rate can be as high as 90%.As the

gasketed plate heat exchanger became apparent that a gasketed

design restricted plate technology in many industrial processes. To

satify this demand, a wide range of welded plate heat exchanger

designs were developed to meet different process requirements.

Welded plate heat exchangers use the same principles as their

gasketed counterpart but employ a fusion weld to seal the fluid

flow channel instead of the gasket. The result is a fully welded

heat transfer plate pack.The advantages of this All Welded Plate

Type Heat Exchanger: The heat exchange core is a fully welded

plate, and the blind plate is connected with bolts, and the

equipment can be quickly installed, disassembled and

convenient to clean The design temperature can reach 350ºC,and

design pressure can reach 3.2MPa The occupied space is

small and can be vertical, horizontal Skew symmetric

channel, turbulent heat transfer efficiency is higher The

short and wide channel combination, suitable for easy blocking

condition Technical Parameters: MediumGas to

Gas, Liquid to Liquid, Gas to LiquidDesign

Temperature:350ºCDesign

pressure3.2 MPaPlate Material:304,316L,AL-6XN,Hastel loy

C-276,254MO,nickel, nickel base alloy

Application field : It is suitable

for Petroleum, chemical, electric power, metallurgy,

shipbuilding, pharmaceutical and other industries Pre-sales

Service: Customization: We

can specially customize products if you tell us any

special requests, such as spare

parts, cylindricaltank, material,

output, pump. .. After-sales

Service: 1. One-year free warranty and life-long

maintenance service 2. Equipment o peration and

maintenance vedio guide for

the c ustomers 3 . Help to do

worker training 4 . On-line support every

day FAQ: 1. Q:Are you a factory or trading

company? A:We are one of the largest heat

exchanger manufactory in China 2.Q:Can we visit your

factory before placing orders? A: Sure, warmly

welcome to our factory! 3.Q:What ' s

the in fo needed if I send one

inquiry ? A : Pls tell us the working conditions, mediums,t emperature ,pressure,

equipment ' s

m ateria l,size,quantity, and other special

requests 4.Q:What is the MOQ? A:MOQ is one complete

set of equipment.5.Q:How does your factory do quality

control? A:Quality is priority ,we make relevant strict

testing before delivery Our factory has already

obtained ISO9001 quality and ISO

14001 Environmental management system certificate /*

January 22, 2024 19:08:37 */!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Industrial Stainless Steel Welded Plate Heat Exchanger Block Structure, ASME Certified

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup