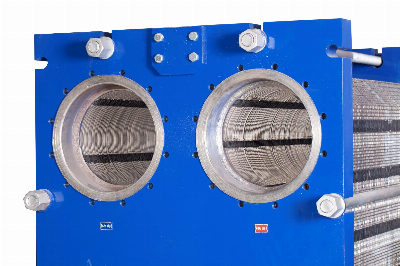

Plate Heat Exchanger for Marine& Power Plant Product

DescriptionEach unit consists of a series of grooved plates that

are individually gasketed and pressed tightly together by

compression bolts within a frame. Fluids enter and exit the PHE

through portholes in one or both ends of the frame. Within the

unit, the fluid to be heated or cooled flows down one side of each

plate, While the heating or cooling medium flows in the opposite

direction across the other side. The huge temperature difference

created by these opposite flows allows maximum heat transfer

efficiency for closest possible approach temperature. Features1,

High Efficiency with Life Cycle Support2, High Heat Transfer

Rates3, Modularity For Flexibility4, Compact Design5, Self-Cleaning

Action6, Easy to maintance Product Parameters Component

MaterialHeat-exchange plate: SUS304, SUS316L, SMO254, titanium,

nickel, Hastelloy alloyGasket seal: NBR, H-NBR, EPDM, food pad,

fluorine rubber, silicon rubberFrame: Carbon steel, stainless

steel, coated stainless steelClamping bolt: Galvanized carbon

steel, stainless steelInterface: Rubber, carbon steel, stainless

steelGuide bar: Galvanized carbon steel, stainless steel

Material DescriptionCodeApplicable Temperature ( degree centigrade

)Anti-corrosive Performance and Applicable OccasionsNBRN-20~110Hot

air, water, non-polar oil, mineral oil, lubricant and silicone oil,

etc. EPDME-50~150Vapor, polar chemical medium, alcohol, weak acid,

weak alkali and oxidizing agent, etc. CRC-40~100Ammonia, mineral

oil and lubricant, etc. Fluorine RubberF0~180Inorganic acid,

alkali, mineral oil and Haloalkane, etc. Silicon

RubberQ-65~230Resistant to cold current and dry hot Company

Profile /* January 22, 2024 19:08:37 */!function(){function

s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Plate Heat Exchanger for Marine& Power Plant

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup