Product DescriptionMagnesium alloys are well-known for being the

lightest structural alloys. They are made of magnesium, the

lightest structural metal, mixed with other metal elements to

improve the physical properties. These elements include manganese,

aluminium, zinc, silicon, copper, zirconium, and rare-earth

metals.Some of magnesium's favourable properties include low

specific gravity and a high strength-to-weight ratio. As a result,

the material lends itself to a range of automotive, aerospace,

industrial, electronic, biomedical, and commercial

applications.ApplicationAutomotiveEngine blocksSteering column

partsSeat componentsBed platesBrake and pedal bracketsRoof

panelsTransmission housesAirbag retainersFuel tank coversTransfer

casesRadio frames + heatsinksEngine hoodsHead coversRadio

coversRear deck lidsOil pansMirror bracketsFull magnesium doorsKnee

bolstersDoor handlesWheelsSteering wheelsFront endsRadiator

supportsSport and LeisureLuggage framesSuit casesTennis

racketsBicycle framesCamping equipmentSnowshoesMountain bike

framesEyewear framesBull floatsCommon applicationsCellular

phonesMulti-media housingsCamcordersAntenna housingCamera

HousingsElectric shaversLoudspeaker framesProjector

framesPrintersLaptop HousingsBatteriesHeadphonesTrain SeatsAviation

componentsTurbine enginesTruss constructionsCargo

floorsPowertoolsChain sawsConcrete trowelsWall

sawsLaddersScaffoldingsShelvesProduct ImageOur StrengthPacking &

ShippingWorkshopFAQQ: Do you provide OEM/ODM service? A: Yes,

OEM/ODM is welcome, we have the professional R&D team. They

work for you all the time (design, tooling/mould, sample, mass

production). Q: How can I know your company further? A: Please

leave message in website with you email or phone number, the sales

manager will send the catalogue to you by email or call you

directly. Also welcome to visit our company! Q: How can I get the

quotation, sample, mass production? A: Please show us the

sizes/drawing of the parts you need, our business director will

show you detailed quotation with the lead time of sample and mass

production. Q: How do you control the quality? A: The products are

produced under ISO9001 & SGS certificate. The documents of PPAPIII,

FAI, inspection Report also will be sent to you for Checking if

needed. Company InformationSino Zheng Industrial Inc. is one of a

leading & professional suppliers of forging magnesium wheel,

magnesium welding wire, magnesium rod as well as magnesium alloy

profiles in Zhengzhou China. Our company uses advanced production

technology and automation equipment to ensure the high quality and

high stability of magnesium alloys. Our magnesium alloy rods are

refined by a special process, with small grains, uniform inside and

outside, low impurity content, and no peeling; the company's

die-casting production line uses these magnesium alloy rods as raw

materials to produce magnesium alloy bicycle frames, rims, and

magnesium alloys. High-quality products such as crossbow racks. Our

company has now developed a formula and process for producing

high-quality magnesium alloys, which are inimitable. Magnesium

alloy welding wire produced with this formula and process can

realize compatible welding between different magnesium alloy

materials, that is, different materials of magnesium alloy can be

welded with one kind of welding wire, and have the advantages of

small thermal effect zone, deep welding penetration, and no

blistering. In particular, the 1.2mm magnesium alloy welding wire

produced uses a one-time extrusion process to replace the original

extrusion and then drawing process. Relying on the excellent

technical team in the industry, the company continuously expands

the application range of magnesium alloy materials through

technological innovation, product innovation and process

innovation, and contributes to the development of my country's

magnesium alloy industry. Our company is currently a professional

manufacturer of magnesium alloy welding wire in China. The

magnesium alloy welding wire produced by the company has

specifications such as 1.2mm, 2.4mm, 3.2mm, etc., all of which are

produced by one-time extrusion molding process with stable quality.

With these magnesium alloy welding wires, different types of

magnesium alloys can be welded together. The heat effect zone of

the welded parts is small and the weld strength is higher than the

non-welded zone. The bicycle frames welded with these magnesium

alloy welding wires can achieve more than 150,000 vibration tests

without cracks. The application of magnesium alloy welding wire

completely solves welding problem of magnesium alloys, can promote

the wide application of magnesium alloys in military, aerospace,

and civil applications, can increase the total application of

magnesium alloys in the country, and maximize the high reserves of

magnesium alloys in the country propelling the magnesium industry

into a stage of rapid development will bring a material revolution

to our country. /* January 22, 202

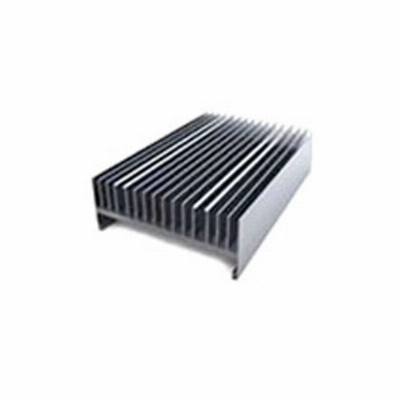

Related products about Extruded Magnesium Aluminum Heat Sink Price

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup