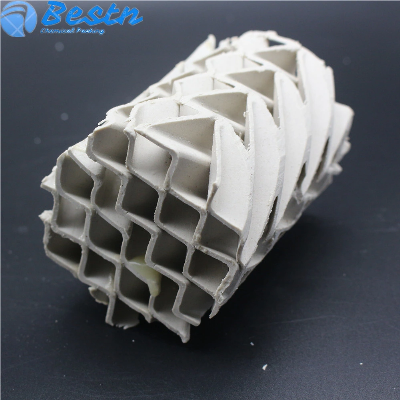

Product DescriptionCeramic structured packing is a kind of

column shape and single layer corrugated packing,consisting of many

moire pieces with the same geometric shape and parallel to each

other. According to the different obliquity of corrugated

sheet,this product is divided into X-style and Y-style,and X and Y

correspond to the 30o and 45o respectively. Ceramic structured

packing has a series of advantages,such as high efficiency,low

pressure drop, great treatment, little liquid content, unremarkable

amplifying effect and high elasticity in operation.With a unique

structure,and excellent hydrophilic performance, the very thin

liquid film can be formed in the surface of ceramic,and the flow of

liquid film as well as oblique and flexural channel ensure the

smooth airflow , and dont impede it,making the efficiency of this

product comparable with metallic corrugated packing. Dohntec makes

the production of different specific surface area and flexible

standard structured packing in terms of customer's demands.Ceramic

structured packing is not only widely used in coal gas washing

tower, fertilizer heat gas saturation tower, naphthalene washing

tower, ammonia washing tower, but also as the support for heat

exchange machine , catalyst, and suit for a big tower

rebuilding/revamp. Type

Application100X The

feature of high corrosion resistance makes it specially suitable

for refinery of oil with high acid value, protecting naphthenic

acid from corrosion. It is a good choice for desulfurization

apparatus and

towers. 250X,Y Widely

used in the process of separation for mineral brine lixiviant

reactant mixture, rectification for organic acid solutions as well

as absorption / desorption for vitriol medium

. 350X,Y Widely

used in the acid dehydrator to reduce reflux, increase acetic acid

and lower column operation temperature. Excellent separation

performance for the process of high vacuum decompression , its

ideal high temperature and corrosion resistant packing material for

the glass, glass fibre reinforced plastic and enamel

tower. 450X,Y Widely

used in absorption, desorption, separation of rectification

for corrosion mixture, requiring the theoretical plate 4-5,

economic loading range: F factor

1.5-2. 700

X Specially

designed for the high mass-transfer efficiency rectification

towers. Dohntec suggest a support grid should be installed

every 3 to 4 meters height of this structured packing.Chemical

AnalysisCompositionValueSiO2≥72%Fe2O3≤0.5%CaO≤1.0%Al2O3≥23%MgO≤1.0%Other0.02 Physical

PropertyndexValueSpecific gravity(g/cm3)2.5Water absorption

(wt%)≤0.5Acid resistance (wt%)≥99.5Loss in burn (wt%)≤5.0Max.

Operating Temp.(ºC)800Crush strength (Mpa)≥130Moh's

Hardness(Scale)≥7Geometric CharacteristicSpec.Specific surfaceBulk

densityVoid ratioObl. AnglePressure drop (mmHg/m)Theo.

plateHydraulic diameter (mm)Liquid load (m3/m2h)Max. Factor m/s

(Kg/m3)-1(m2/m3)(kg/

m3)(%)(m-1)250Y2504208045022.5120.2-1002.6350Y350470784502.52.8100.2-1002.5400Y400500754503380.2-1002450Y450520724504470.2-1001.8550Y550620744505.55-660.18-1001.4700Y700650724506750.15-1001.3250X250380803002.52.3120.2-1002.8350X3504507830032.5100.2-1002.6400X4004807530042.880.2-1002.2450X450500723004.53-470.2-1002470X470440753005570.2-1001.8550X550620743005.55-660.18-1001.4700X700650723006750.15-1001.3Advantage1.High

capacity. New tower design may reduce diameter, while renovate old

towers may increase capacity significantly.2.High separation

efficiency. Since it has much larger specific surface area compared

to random packing.3.Low pressure drop, which leads to reduce energy

consumption largely.4.Large flexibility, and scale effect is not

obvious.5. Suitable for all tower diameters.6.Strong resistance to

corrosion of acid and alkali, especially to H2S, naphthenic acid

and Cl- .Applications1. Rectifying organic

halide.2. Rectifying and absorbing some corrosive mixtures,

which are definitely regulated in pressure drop and theoretic plate

number.3. Applied in some towers that contain a large quantity

of natural media used to absorb nitric acid and concentrated

sulfuric acid, as well as for purifying the air in chemical

plants.4. Operating in vacuum conditions at a bottom absolute

pressure of 100pa.5. Used in heat exchanger and demisting, or as a

catalyst carrier. /* January 22, 2024 19:08:37

*/!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Rto Ceramic Structured Packing as Heat Recovery Media

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup