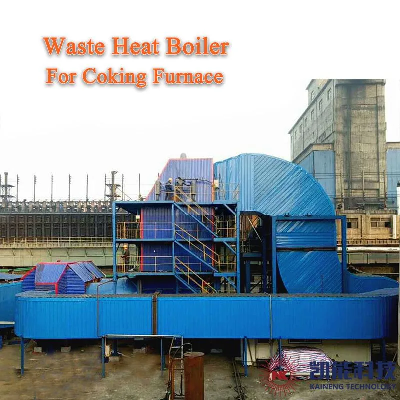

Flue Gas Waste Heat Recovery Steam Generation Exhaust Gas Boiler

For 500000~2000000 Tons Corking FurnaceDescription of Exhaust Gas

Boiler:Description of Exhaust Gas Boiler:The exhaust gas boiler

adopts forced circulation, that is, steam and water working fluid

are driven by external force (feed water pump, hot water

circulation pump) in the pipe. This can make the heating surface

layout very compact and without any restrictions.Heating surface of

waste heat boiler consists of 2 parts:1. Economizer2. Evaporator.

Exhaust gas boiler is installed in the flue duct of the Coking

furnace tail to achieve the purpose of recovering waste heat of

flue gas and protecting the environment. It is of great practical

significance to effectively reduce energy consumption and promote

the sustainable development of renewable energy.Exhaust Gas Boiler

capacity:Exhaust gas boiler (EGB) are offered in tailor-made

capacities as per customer requirement Product

parameter (for reference only, Waste Heat Boiler Customization

Available): S.NItemDescription1Exhaust gas

flow157000Nm3/h2Exhaust gas inlet280ºC3Steam

capacity8.5t/h4Operating pressure (MPa)0.8 MPa5Design pressure

(MPa)0.9 MPa6Rated steam temperature175.4ºC7Exhaust gas

outlet160ºC8Pressure drop

Related products about Flue Gas Waste Heat Recovery Steam Generation Exhaust Gas Boiler

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup