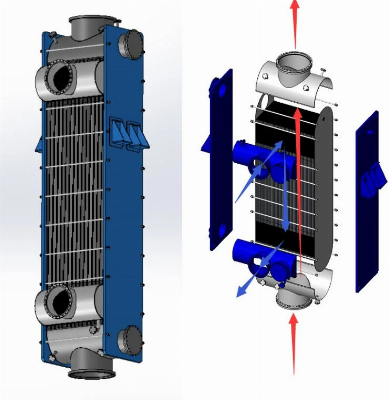

Based on the advantages of foreign research on fully welded plate

heat exchangers, our company has specially designed and developed a

new type of countercurrent lean rich liquid heat exchanger for

carbon dioxide capture projects. The fully welded wide channel

plate heat exchanger is composed of basic components such as the

plate stack, Panels, clamping plates, Heater, bolts, nuts, sealing

gaskets, split partition plates, supports, etc. The heat transfer

core are fully welded plate stack. Product Description

Plate heat exchanger is an ideal equipment for heat exchange

between liquid and steam. The utility model has the advantages

of high heat exchange efficiency, small heat loss, compact and

light structure, small floor area, wide application, long

service life, etc. Under the same pressure loss, the heat

transfer coefficient is 3-5 times higher than that of the tube heat

exchanger, the floor area is one third of the tube heat

exchanger, and the heat recovery rate can be as high as 90%.

Product Name:Welded Plate Heat

EXchanger Certification:ASME API ISOWorking

Pressure:Max.1MPaPlate Material:SS Duplex steelWorking

Temperature:Max.400°CFrame Material:Carbon SteelPlate

Thickness:1-1.6mmDelivery Time:30 Days Wintech ammonia Heat

exchanger Advantage: 1. Higher heat exchange

effeciency The use of counter current heat exchange can avoid

temperature crossing, small temperature difference at the end and

other problems, thus significantly improving the heat transfer

performance, making the heat transfer effect Heat transfer

coefficient higher and the heat transfer effect better. 2. The

equipment flow channel is smooth and not easily blockedThe patented

design version has both sides of the channel being a straight

channel on one side, which is not prone to blockage 3. Less

pressure dropThe plate can be made longer, the overall flow on the

cold and hot sides is less, the fluid does not need to change the

flow direction for many times to produce unnecessary Friction loss,

and both cold and hot sides are straight channels, which are easier

to flow and have less resistance 4. Larger single unit areaThe

plate form is a rectangular long plate, with a single plate area of

up to 10m2 and a single heat exchange area of up to 3000m2. For

working conditions with larger heat exchange areas, there are fewer

plate and shell heat exchangers, which can save costs

more. Company ProfileAbout usShandong Wintech Technology Co.,

Ltd. is engaged in engaged in the design, fabrication,

installation and commissioning of specialised heat exchange

equipment, required by the oil and gas, petrochemical engineering,

chemical industry, waste incineration plant, food processing plants

and other engineering undertakings. The company is capable of

fabricating products in accordance to major international codes or

specifications in carbon steel, stainless steel, alloy and

non-metallic materials.Two scientific research centers were

cooperated with universities:1. Technology-Wintech Thermal

Technology Research Institute, cooperated with Qingdao University

of Science.2. Wintech Carbon Dioxide Capture Research Laboratory,

cooperationed with Zhejiang University. • More than 30

experienced engineers, who will present the tailor-made project

scheme of heat exchanger. • supplier of SINOPEC, PetroChina,

SONNC CNOOC and National Power.• Heat exchanger supplied to

Evironment Engineering companies for denitration and

desulfurization systerm. Products ExhibitionWhy Choose UsWe

set up all art state of facilities on processing from the uncoiling

steel machine, hydraulic oil pressing machine, Gantry

milling, resistance welding machine, welding robot, Laser welding

machine,testing from complete instruments in our lab, make every

set of equipment is dispatched at the qualified

controlling. Basing on our powerful product capability, many

certification and awards are achieved. ISO14000, ISO9000,

OHSAS18001, CNAS, IAF, ASME make us prodce and supply equipment as

per the ASME standard complying with international market

consumption, now our clients are from Russia, Uzbekistan, Thailand,

South America, India,Indonesia, Malaysia,Iran, Saudi Arabia,

Argentina, and other countries and areas.After-sales

Service: 1. One-year free warranty and life-long

maintenance service 2. Equipment o peration and

maintenance vedio guide for

the c ustomers 3 . Help to do

worker training 4 . On-line support every

day FAQ:1. Q:Are you a factory or trading

company? A:We are one of the largest heat

exchanger manufactory and factory.2.Q:Can we visit your

factory before placing orders? A: Sure, warmly

welcome to our factory! 3.Q:What ' s

the in fo needed if I send one

inquiry ? A : Pls tell us the working conditions, mediums,t emperature ,pressure,

equipment ' s

m ateria l,size,quantity, and other special

requests 4.Q:How will the heat exchange be shipped? A:

auto transportion, train, sea shipment. 5.Q:How does your

factory do quality control? A:Quality is priority,

quality plan will be pres

Related products about Large Scale Ammonia Heat Exchanger Used in C Capture System

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup