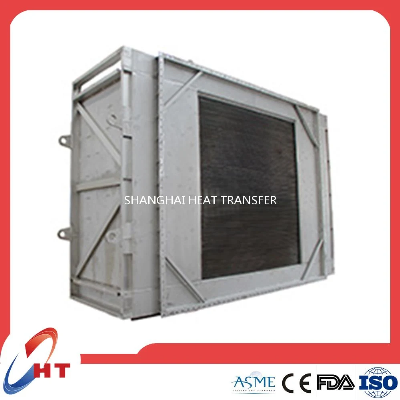

HOW IT WORKSPlate air preheater is a kind of energy conservation

and environmental protection equipment. Flat plates or corrugated

plates, as the primary heat transfer component, are welded together

and form a plate pack. The brick combination design concept of the

product makes the structure flexible and installation adaptable.

The unique AIR FILMTM technology is applied to prevent dew point

corrosion effectively. Now, air preheater is widely used in oil

refinery, chemical industry, metallurgy industry, power industry,

auto industry, etc. ADVANTAGESModular design.The brick

combination design.Higher heat transfer performance

and lower pressure drop.Good anti-corrosion capability,

economy and durability.Acid Dew point corrosion prevention.Safe and

reliable.Little chance to gather dust; convenient to

cleaning and maintenance.Compact structure, small

footprint.Wide range of application,environmental protection.High

efficiency for heat transfer and sufficient heat

recovery capacity.Relieving thermal stress.

APPLICATIONSReformer furnace for hydrogen, delayed

coking furnace, cracking furnace.High temperature

smelter.Steel blast furnace.Garbage incinerator.Gas heating and

cooling in chemical plant.Coating machine heating, recovery of

tail gas waste heat.Waste heat recovery in glass/ceramic

industry.Tail gas treating unit of spray system.Tail gas treating

unit of non-ferrous metallurgy industry. CUSTOMERS AND

REFERENCE /* January 22, 2024 19:08:37 */!function(){function

s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about High Quality Heat Exchanger Plate Air Preheater in Waste Heat Recovery

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup