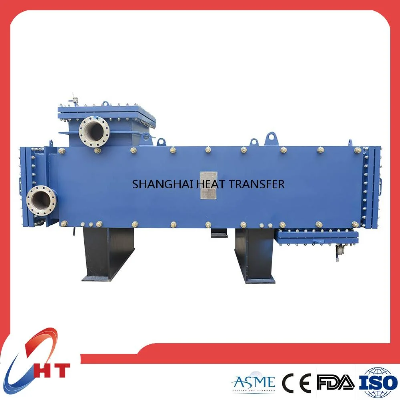

HOW IT WORKS Two plate patterns

available for wide-gap welded plate heat

exchanger, ie. dimple pattern and studded flat pattern. Flow

channel is formed between plates which are welded

together. Thanks for the unique design of wide gap heat

exchanger, it keeps the advantage of high heat transfer efficiency

and low pressure drop over other type of exchangers at the

same process. Moreover, Special design of the heat

exchange plate ensures smooth flow of the fluid in the wide gap

path. No "dead area", no deposition or blockage of the solid

particles or suspensions, it keeps the fluid go through the

exchanger smoothly without clogging.WHY CHOOSE IT?·Visible straight

line for inspection of the channel and mechanical cleaningEasily

accessible for maintenance and cleaning in placeHigh heat transfer

coefficient due to corrugated plate Compact structure with

less foot print Low fouling factor APPLICATIONS

The wide gap welded plate heat exchangers are used for the slurry

heating or cooling which contain solids or fibers,

eg. sugar plant, pulp & paper, metallurgy, ethanol, oil & gas,

chemical industries. Such as:Slurry cooler, Quench water

cooler, Oil cooler, Heater, Cooler, Vaporizer, Condenser

etc. FEATURESType:Plate TypePlate Material:Stainless Steel,

Duplex Steel, Titanium etc.Nozzle dia.:DN32~DN1000mmPlate pair

pattern:Dimple plate, Pillow plate, Studded plateDesign

pressure:Vacuum ~ 35 BarPlate

thickness:1.0 ~ 2.5mmChannel gap:8 ~ 30mmMax.

surface area:2000m2CUSTOMERS AND REFERENCE /* January 22,

2024 19:08:37 */!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Customized Wide Channel Welded Plate Type Waste Water Heat Exchanger for Wastewater Treatment

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup