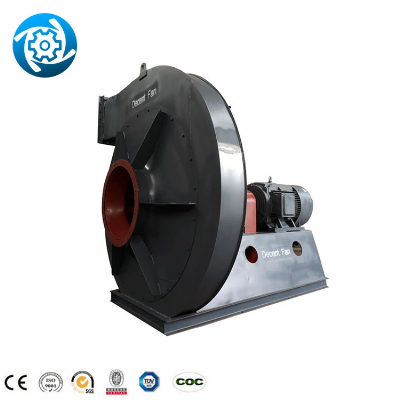

Blower is also commonly known as Centrifugal Fans in industry. In a

blower, the inlet pressure is low and is higher at the

outlet.Industrial Boiler Centrifugal Fan Blower PriceWe supply HIGH

-PRESSURE BLOWERS for various industrial applications. Key

features:& With single suction fan, length of alternating with

forward curved blades impller made of high strength wear resistant

steel materia single.Belt drive or clutch

transmission.Advantages: 24*7 hours online service More

than 100 customers visited us and felt very satisfiedExported to

over 80 countriesCE,ISO,SGS,ETA,MA,AMCALive video for the workshop

by WhatsApp wechat or youtube. Oversee technical support at

your siteBetter customers' experience after sales: we visit our

customer each yearProduction according to your drawing(2D/3D)Famous

motor brand(Siemens/ABB/TECO/WEG)High standard quality control-

Testing video/Testing report availableWelding / Materials testing

report availableSurface Treatment: automatic electrostatic powder

coating ( ie spray) or spray paint.Corrosion protection and rust

removal treatmentTracking number for each equipment available

Feature:• IP 55/65• 50hz/60hz• Corrosion Proof•

220v/380v/415v/440v/660v/1140v• 1450RPM/960RPM/720RPM/590RPM• High

Temperature Proof (up to 500 °C)• Each

fan's impeller has been well dynamic

balanced.Structure:♦ Impeller Type: Backward/Forward/

radial blade♦ Driving Mode: Direct/belt/Coupling

drivetrain♦ System Type: Single inlet type, Overhang

type.♦ Cooling Type: Air cooling/Circulating Water

cooling♦ Bearing Lubrication Methods: Grease

lubricating/Oil bath lubricationMotor

Brand: ABB /Siemens /Baldor /

Teco/ Westinghouse Motor ♦ Basic

Components: Motor, Impeller, Impeller cone (Air Inlet), Case,

Main shaft, Bearing, Bearing housing, Pin coupling, Foundation

bolt. System monitoring Instrument, Lube system,

Overhead lube tank... Application:Building ventilation/Oven

exhaust/Drying systemMoisture blow-off/Fume removal/Glass

temperingSpray-booth exhaust/Air curtains/CoolingDust

collection/Air recirculation/Pneumatic conveCombustion air /Food

processing VentilatingForced ventilating, Building

ventilating, Mine ventilating, Tunnel ventilating, Materials

ventilating and drying. ♦ Cooling and heat

dissipationForced cooling and heat dissipation, Industrial

equipments cooling and heat dissipation. ♦ Air

purification and industrial waste gas treatment, Air filtration

system, Flue gas desulfurization, Flue gas

denitrification. ♦ Boiler's air supply and exhaust

(Coal-fired boiler, Biomass boiler, Garbage incinerator, CFB

boiler, Stokerfeed boiler.). ♦ Industrial

boiler blowing air, Industrial boiler inducing air, Industrial

boiler primary air, Industrial boiler secondary

air. ♦ Industrial boiler waste gas desulfurization,

Industrial boiler flue gas denitrification. ♦ Industrial

kilnsInducing air of Cement rotary kiln, Lime rotary kiln, Nickel

iron rotary kiln, Clay sand rotary kiln, and other various

calcining kilns.Garbage incinerator blowing air, Garbage

incinerator inducing air, Brick kiln inducing air.Ventilating of

cement mill, Coal mill and other large mill

system. ♦ Energy and power: Thermal power plant, Garbage

incineration power plant, Biomass fuel power plant, Industrial

waste heat recovery device. ♦ Metal smelting: Blowing air

of mineral powder sintering(Sintering machine), Furnace coke

production(Furnace coke oven). ♦ Gas and materials

delivery: General air delivery, High-temperature air delivery,

Combustible gas delivery, Corrosive gas delivery, Gas mixed with

impurity delivery.Delivery of coal powder, Particle material/

Powder material/ Fragment materials/Fiber

materials. ♦ Other:Pressurization and decompression seal

of industrial equipment, Recovery of industrial waste gas, Supply

air and drying of food and drug production

line. Characteristics of Single Inlet

Industrial Boiler Centrifugal Exhaust Fan 2500

cfm ♦ Outputting higher gas pressure, and providing

larger air flow volume, low noise. ♦ Blades angle going

through optimizing design, higher wear resistant, longer service

life. ♦ Can flexibly adjust fan's volume and pressure in

running by air damper. Can also adjust fan's pressure and volume by

changing the fan speed via matching variable frequency

motor. ♦ In the case of using system base, so easy for

installation, no need of professionals

direction. ♦ Transmission efficiency higher than belt

driving's, much lower of fan system energy

loss. ♦ Flexible connection for motor shaft and

transmission shaft, no need to tension or change the belt, low

maintenance work exhaust fan. ♦ Fan system whose

impeller's diameter below 1400mm, is not needed to match bearing

cooling device, can reduce the customer's cost and maintenance

work. ♦ Can satisfy different dust loading conditions

that low dust loading to a good deal dust loading, the surface

hardness of impeller can reach to HRC60~70 after special

processing, greatly extending impeller's service

life. ♦ Using liquid lubricating oil, no need to ope

Related products about China API Standard 673 Large Supply Medium Supply Fan to Blow Air Through Air Heat Exchangers for Building Machines for The Horticulture Industry.

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup