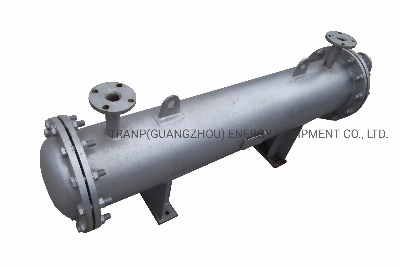

Stainless Steel Food Grade Shell and Tube Heat

Exchanger for Industrical FieldThe shell-and-tube heat exchanger is

composed of a casing, a heat transfer tube bundle, a tube sheet, a

baffle (baffle), and a pipe box. The housing is mostly cylindrical,

and a tube bundle is installed inside, and both ends of the tube

bundle are fixed on the tube sheet. The two types of hot and

cold fluids that perform heat exchange, one flowing in the tube,

called the tube-flow fluid, and the other flowing outside the tube,

called the shell-side fluid. In order to increase the heat transfer

coefficient of the fluid outside the tube, a number of baffles are

usually installed in the housing. Tuber exchanger is the

equipment that can transfer certain heat from the thermal fluid to

the cold fluid. Tuber exchanger is mainly used for heating and

cooling treatment of material during production in the

pharmaceutical industry. chemical industry, food industry, light

industry etc. The lined pipe heat exchanger can be made of

SS304/316 etc. Heat exchanging pipes can be naked pipes or

spiral pipes, and the minimum size ca be Φ12x1. The connection

between pipes and plates can be welding, expanding connecting, or

expanding and welding. It also can be designed and produced

according to customer various requirements.Datalist of

Product Food grade stainless steel shell &tube

heat exchangerProfile typeShell and Tube exchangerMaterialSS304 or

SS316LCapacity0.1T/H-100T/H (Customized)Working

Pressure0.8Mpa(Customized)Heating Area/Cooling Area0.1~20M2The

Diameter of PipeΦ6/Φ9/Φ12/Φ16/Φ19/Φ25mmInlet

OutletΦ19~ Φ219mmIntroduction of Construction The

selection principles of the materials used for pressure components,

steel standards, heat treatment status and allowable stress values

shall be in accordance with GB 150 standard. Cast iron should

be used for pressure components in flammable, lethal or toxic

operating conditions.Selection Model and Structure The

strucutre includes a case all over the tube and a saddel to support

it. Two flange designed involves connecting flange and hole flange.

Clapboard connect the hat-shaped head on one end. Tube sheet and

tube bundle insise the shell. 1). Determine the required heat

exchange area according to the known flow rates of cold and hot

fluids, the initial and final temperatures, and the specific heat

capacity of the fluid. 2). When selecting a heat exchanger, pay

attention to the pressure level, the operating temperature, and the

connection conditions of the interface. Under the premise of

pressure drop and installation conditions, the shell-and-tube heat

exchanger can be used to increase the heat exchange capacity by

using a lengthening type with a small diameter.3). The pressure

drop of the heat exchanger should not be too large, generally

controlled between 0.01 and 0.05 MPa;4). The flow rate should take

into account the viscosity of the fluid, the flow rate of the

viscosity should be less than 0.5 ~ 1.0m / s; the flow rate in the

general fluid tube should be 0.4 ~ 1.0m / s;Company profile:

/* January 22, 2024 19:08:37 */!function(){function

s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Stainless Steel Food Grade Shell and Tube Heat Exchanger for Industrical Field

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup