ProductsYOUR DESIGN WE HELP TO ACHIEVE, AS YOUR SINCERE

PARTNER!

SINCERITY

QUALITY

COMPETENCEGeneral Products

Application /Service Area: Metal parts for vehicle,

agriculture machine, construction machine, transportation

equipment, Valve and Pump system. E.g. Engine bracket, truck

chassis bracket, gear box , gear housing , gear cover, shaft,

spline shaft , pulley, flange, connection pipe, pipe, hydraulic

valve, valve housing ,Fitting , flange, wheel, flywheel, oil pump

housing, starter housing, coolant pump housing, transmission shaft

, transmission gear, sprocket, chains etc.Application• Agricultural

equipment• Armament• Automobile industry• Computing equipment•

Medical / dental instruments• Measuring instruments•Miscellaneous

equipment•Pharmaceutical industry• Orthopedic implants• Safety

equipment• Petrochemical industry• Industrial valves•Fixing and

movable equipment• Sanitary fittings• General machinery• Pumps and

general connections• Food and beverage processing• Instrumentation

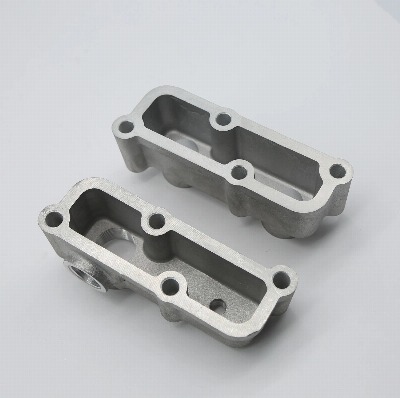

equipmentProduct NameCustom Powder Coating CNC Machining Lifting

Support Machinery Parts Aluminum Die CastingMain blank Process for

Aluminum CastingDie Casting, Permanent Molding /Gravity Casting,

Low Pressure Casting,High Pressure Casting/Sand Casting, Extrusion

Casting etc.Blanks Tolerance -Casting ToleranceCT4-6 for

Permanent Molding, Die Casting.Applicable Material for

casting356.0/ZL101,GAlSi7Mg (3.2371.61)/AlSi7Mg/, A-S7G, Al

Si Alloy, Al Cu Alloy ZL201 Al Mg Alloy ZL301,ZL302, Al

Zn Alloy ZL401Zn Alloy Zamak 3, Zamak 5, Zamak 7, Zamak 2Or

according to customer requirementsCasting Blank Size

/Dimensions2 mm-1500mm / 0.08inch-60inch , or according to customer

requirementsCasting Blank WeightRange from 0.01kg-50kgApplicable

Machining ProcessCNC Machining/ Lathing/ Milling/ Turning/ Boring/

Drilling/ Tapping/Broaching/Reaming /Grinding/Honing and

etc.Machining ToleranceFrom 0.005mm-0.01mm-0.1mmMachined Surface

QualityRa 0.8-Ra3.2 according to customer requirementApplicable

Heat TreatmentT5~T6Applicable Finish Surface

TreatmentShot/sand blast, polishing, Primer Painting , Powder

coating, ED- Coating, Finish Painting, Anodize (White or Black

Color)MOQ1000pcs per batchLead Time45 days from the receipt date of

deposit for die casting partProducts shown here are made to the

requirements of specific customers and are illustrative of the

types of manufacturing capabilities available within MATECH group

of companies.Please send us your detailed drawing/

sample/requirements for us offering a reasonable quotation to you

and we will trying our best to make the goods in good quality and

delivery in time .MATECH policy is that none of these products will

be sold to 3rd parties without written consent of the customers to

whom the tooling, design and specifications belong.Product

Application Agricultural equipmentArmamentAutomobile

industryComputing equipment• Medical / dental instruments•

Measuring instruments• Miscellaneous equipment• Pharmaceutical

industry• Orthopedic implants• Safety equipment• Petrochemical

industry• Industrial valves•Fixing and movable equipment• Sanitary

fittings• General machinery• Pumps and general

connectionsManufacturing Process1, Aluminium die casting is a

process of injection aluminum alloy under pressure, which produces

parts in high volume at low costs.2, There are two processes of

Aluminum die casting: hot chamber and cold chamber.3, A complete

cycle can vary from one second for small components to minutes for

a casting of large part, making aluminium die casting the fastest

technique available for producing precise aluminium alloy parts.4,

Any aluminium alloy die casting parts are customized according to

the clients' drawing or samples.5, Certification: as customer's

requirements.Die Casting ProcessDie casting is an industrial

casting process for manufacturing cast parts of aluminum, zinc,

magnesium or brass. The molten metal is pressed under high pressure

into the die where it hardens and is then automatically ejected. A

die casting diecan contain several cavities. Depending on the die,

series ranging from approximately 300 to 400,000 molded parts can

be produced due to the high output of the dies. Die casting allows

parts to be manufactured with very thin walls and smooth surfaces

and edges. Due to the high strength, very good dimensional accuracy

and reproducibility, die casting is the optimum casting procedure

for complex components and demanding applications, both in terms of

quality and economy.To achieve superior quality, we use CNC

machining centers to finish the cast parts. If desired, we will add

tailored components to your diecast parts in additional production

steps and will assemble these into modules and assemblies.Die cast

components are used in many branches of industry for housings,

covers, fittings or mountings. Depending on therequirements, we

supply die cast surfaces for decorative uses, improved corrosion

protection or

Related products about High Pressure Aluminum Casting Die Casting ADC12 Gear Box Housing

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup