Technical data:1,output torque:200-50000(N.m)2,rated

power:0.18-200(kw)3,input speed:≤1500 (rpm)4,output

speed:≤280(rpm)5,transmission ratio:≥5.366,series:37,install

form:M1-M68,Model no.

:K/KA/KF/KAF/KH/KHF(37/47/57/67/77/87/97/107/127/157/167/187)Other1,Driving

in a variety of forms: motor straight league, user with motor,

pulley, wheel drive, couplings straight league drive,

the handwheel device etc2,Output in a variety of forms: can hollow

shaft output and solid shaft output, hollow shaft flange and solid

shaft flange, hollow shaft torque arm type, solid shaft torque arm

type, etc3,Installed in a variety of forms: can base mounting,

flange installation, torque arm installation,

etcType37475767778797107127157167187Structure formK KA KF KAF KAZ

KAT KABInput

power(KW)0.18-30.18-30.18-5.50.18-5.50.37-110.75-221.1-303-457.5-9011-16011-20018.5-200Transmission

ratio5.36-106.385.81-131.876.57-145.147.14-144.797.24-192.187.19-197.378.95-176.058.74-1410.468.68-146.0712.65-150.4117.28-163.91170.27-180.78Allowable

torque(N.m)200400600820155027004300800013000180003200050000Weight(kg)11202733578513025038061010151700 Product

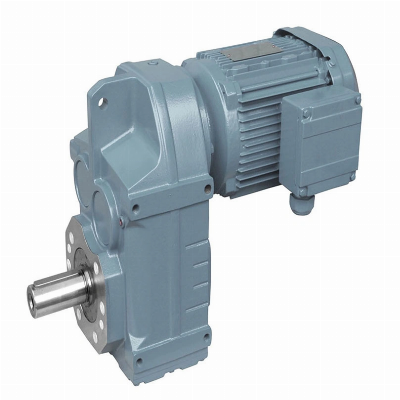

Description-K Series Helical Bevel Gearbox K series gear

reducer, manufactured according to international technical

requirements, has a high scientific and technological content;

Space saving, reliable and durable, high overload capacity, power

up to 132KW; Low energy consumption, superior performance, reducer

efficiency up to 95%It is designed and manufactured on the basis of

module combination system. There are a lot of motor combinations,

installation forms and structural schemes. The transmission ratio

is classified carefully to meet different operating conditions and

realize electromechanical integration.High transmission efficiency,

low energy consumption and superior performance.Reinforced high

rigid cast iron box; The hardened gear is made of high-quality

alloy steel. Its surface is carburized, quenched and hardened, and

the gear is finely ground. It features stable transmission, low

noise, large bearing capacity, low temperature rise, and long

service life. Performance and characteristics:1. The gear is

carburized and quenched with high-quality alloy, the hardness of

the tooth surface is up to 60 ± 2hrc, and the grinding accuracy of

the tooth surface is up to 5-62. The computer modification

technology is used to pre modify the gear, which greatly improves

the bearing capacity of the reducer3. Complete modular structure

design is adopted from the box to the internal gear, which is

suitable for large-scale production and flexible selection4. The

standard reducer models are divided according to the form of

decreasing torque. Compared with the traditional equal proportion

division, they are more in line with customer requirements and

avoid power waste5. It is designed and manufactured by cad/cam to

ensure the stability of quality6. Multiple sealing structures are

adopted to prevent oil leakage7. Multi directional noise reduction

measures to ensure the excellent low noise performance of the

reducer8. The installation mode of Liyi products is flexible, which

makes it easy for customers to choose K57 reducer, K67 reducer, K77

reducer, K87 reducer, K97 reducer, KA87 reducer, KA97 reducer,

KA107 reducer, KA127 reducerProduct Features1. Input mode: Coupled

motor, belted motor, input shaft or connection flange.2.

Output: Right angle3. Compact structure. Rigid tooth

face. Carrying greater torque, high loading capacity.4.High

precision gear, ensuring the unit to operate stably, smooth

transmission.5. Low noise, long lifespan. Large overlap

coefficient, abrasion resistant.Our process of productionOur

product line/* January 22, 2024 19:08:37 */!function(){function

s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about K Series Helical Bevel Gearbox Flange Motor Transmission Machine Worm Motor Gear High Quality Reducer Speed Increaser

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup