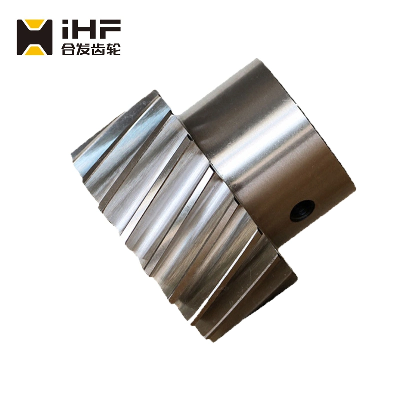

OEM ODM Custom Precision Steel Machining Forged Spur Plastic

GearsGear transmission relies on the thrust between gear teeth to

transmit motion and power, also known as meshing transmission. With

this gradual meshing, helical gears operate much more smoothly and

quietly than spur gears. Therefore, almost all automobile

transmissions use helical gears.Since the teeth on the helical gear

present a certain angle, the gears will be under a certain amount

of stress when they mesh. Equipment using helical gears is

equipped with bearings to withstand this pressure.Product

DescriptionProduct namehelical

gearMaterials AvailableStainless Steel, Carbon

Steel, Brass, Bronze, Iron, Aluminum

Alloy,Copper,Plastic etcHeat TreatmentQuenching & Tempering,

Carburizing & Quenching, High-frequency Hardening,

Carbonitriding......Surface TreatmentCarburizing and

Quenching,Tempering ,Tooth suface high quenching

Hardening,TemperingBOREFinished bore, Pilot Bore, Special

requestProcessing MethodMolding, Shaving, Hobbing, Drilling,

Tapping, Reaming, Manual Chamfering, Grinding etcPressure Angle20

DegreeHardness55- 60HRCSizeCustomer Drawings & ISO

standardPackageWooden Case/Container and pallet, or

made-to-orderCertificateISO9001:2008ApplicationsElectric machinery,

metallurgical machinery, environmental protection machinery,

electronic and electrical appliances, road construction machinery,

chemical machinery, food machinery, light industrial machinery,

mining machinery, transportation machinery, construction machinery,

building materials machinery, cement machinery, rubber machinery,

water conservancy machinery and petroleum machineryMachining

ProcessMaterial preparation, normalizing, rough turning, quenching

and tempering, semi fine turning outer circle, rough turning spiral

surface, fine turning (fine grinding) inner hole end face, keyway,

semi fine turning spiral surface, pliers (rest incomplete teeth),

semi fine grinding outer circle, semi fine grinding spiral surface,

grinding center hole, fine grinding outer circle, fine grinding

spiral surface, finished product inspectionAdvantages1. Produce

strictly in accordance with ANSI or DIN standard dimension2.

Material: SCM 415 steel 3. Bore: Finished bore4. Precision

grade: DIN 5 to DIN 75. Surface treatment: Carburizing and

Quenching6. Module: From 1 to 47. Tooth: From Z15 to

Z70Specifction: NumberNumber of TeethShaft Bore Dia. AH7 (1mm

Increment)Twisting DirectionBCDEFGTypeModuleStraight Bore Straight

Bore+TapKeyway+TapStraight BoreStraight

Bore+TapKeyway+Tap 1.02068L(Left)R(Right)1720228101822~

2888~1318~2022~2824~3030~481010~1725~3030~4832~5050~701212~1735~4050~7052~7280~1001515~305080~10082~1021.520~261212~1724~3230~3933~4212122428~441515~3036~5042~67.545~70.545~521818~4050~6072~7875~8160~1002020-5060~7090~15093·1532.015~181212~1724~3030~3634~4016132920~281515·2232~4540~5644~6030~361818~405060~7264~7640~482020~446080~9684~10050~1002525~6060~100100~200104~2042.515~181515~3030~3837.5~4542.5~5020143420~241818~4040~4850~6055~6525~362020~5050~7062.5~9067.5~9540~602525~7070~8090~15095~1553.015~181818~2236~4045~5451~6025164 Company

ProfilePackaging & ShippingFAQMain Markets?North America, South

America, Eastern Europe , West Europe , North Europe, South Europe,

AsiaHow to order?* You send us drawing or sample* We carry through

project assessment* We give you our design for your confirmation*

We make the sample and send it to you after you confirmed our

design* You confirm the sample then place an order and pay us 30%

deposit* We start producing* When the goods is done, you pay us the

balance after you confirmed pictures or tracking numbers.* Trade is

done, thank you!! If you are interested in our products,

please tell us which materials, type, width, length u want./*

January 22, 2024 19:08:37 */!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about OEM ODM Custom Precision Steel Machining Forged Spur Plastic Gears

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup