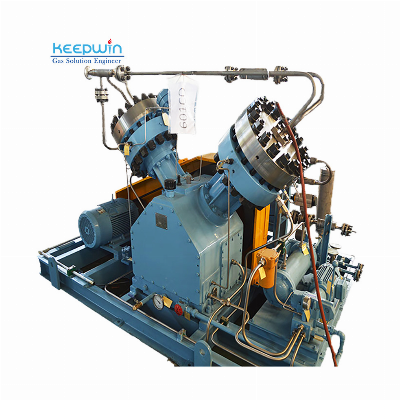

Diaphragm Compressor 100% purity no leakage Oil-free Helium Gas

Booster Compressor The diaphragm compressor booster is

a special structure of the volume-type compressor with high

compression ratio, good leak tightness, compressed gas without

lubricating oil and other solid impurities contaminated features,

So it's suitable for high purity compression, rare, valuable,

inflammable, explosive, toxic, harmful, corrosive, and high

pressure gasAdvantages of Diaphragm compressor:1. Oil-free

compression due to the hermetic separation between gas and oil

chamber.2. Abrasion-free compression due to static seals

in the gas stream3. Automatic shutdown in case of

a diaphragm failure prevents damage4. High

Compression Ratios-Discharge pressure up to

1000bar.5. Contamination Free Compression6.

Corrosion Resistance7. High ReliabilityAs

a displacement compressor with special,diaphragm compressor is

characterized by large compression ratio,good sealing

performace,and that the compress air will not be polluted by

lubricant or other solid impurities.Therefore diaphragm compressor

is applicable to compress high-purity,rare and precious,flammable

and explosive,toxic and hazardous,corrosive and high pressure

gases.Keepwin diaphragm compressors consist of four types that are

Z,V,L and D type.The exhaust pressure ranges from 1.3 to 100

Mpa. The products are widely used in the industries of national

defense,scientific research,petrochemical,nuclear

power,parmaceutical,food-stuff and gas separation.Helium

compressors are widely used in Petrochemicals, Fine Chemicals,

Pharmaceutical Chemicals, Energy Chemicals, Machinery Industry,

Electronics Industry, Agriculture, Animal Husbandry and Defense

Industry.It is mainly used in Vacuum Systems for Evaporation,

Sputtering and Ion Implantation of Semiconductor front-end process

equipment, and also has a wide range of applications in Astronomy,

Aerospace, Medical and other fields. Inquiry to us!Note:for

the other customizing process gas compressor, please kindly send

below information to our factory to calculate the producing cost

for your item.Clients' inquiries should contain related

parameters A. The gas compression medium B. Gas

composition? or the gas purity?C. The flow rate: _____Nm3/hrD.

Inlet pressure: _____ Bar (gauge pressure or absolute pressure)E.

Discharge pressure: _____ Bar (gauge pressure or absolute

pressure)F. Inlet temperatureG.Discharge temperatureH. Cooling

water temperature as well as other technical requirement.Technical

Paramter of Oil Free Diaphragm CompressorGZ type Diaphragm

Compressor Technical ParametersNo.ModelF.A.D (Nm3/min)Inlet

Pressure ( Mpa)Exhuast

Pressure (Mpa)Power (KW)Speedr/minDimension(L×W×H)mmN.W Weight

(t) VoltageV1G2V-10/8-160100.8165.54001550*900*10500.83802G2V-5/3.5~15050.35155.54001550*900*10500.83803G2V-10/4~320100.4325.54301650*850*12500.83804G3V-240/5~122400.51.218.54001860*1200*158523805G3V-1200/75~8312007.58.318.54001780*1050*17501.83806G3V-80/13~150801~1.515223302400*1350*14652.13807G3V-30/5~315300.531.5154002010*955*14551.83808G3V-80/7~150800.715224002302*1385*14442.53809G2V-25/6~150250.6157.54001500*775*10750.838010G2.5V-10/16010Normal167.54001650*1020*14000.9538011G2.5V-20/1~160200.116114001650*1020*14000.9538012G2.5V-16/2.5~160160.25167.54001650*1020*14000.9538013G3V-100/24~1251002.412.5224002160*1250*15001.838014G4V-220/99-3492207.0~2534.9374002492*1840*16103.238015G2Z-45/150~3504510~20357.54001610*790*13800.5538016G2Z-5/30~40053405.54001560*790*14700.5538017G2.5Z-30/32~170303.2177.54001550*650*15300.738018G3Z-600/75~836007.58.3114001780*1050*17501.338019G3Z-85/100~350855~253518.54001900*1240*17601.638020G3Z-150/150~350150153518.54001780*1050*17501.838021G2.5Z-40/7~30400.737.54001653*1372*14700.938022G2.5Z-100/20~3510023.55.54001330*750*15300.938023GV3-110/8~1501100.815304002370*1458*1630338024G3V-150/3.5~301500.35~0.553304002543*1835*20363.2138025G3V-60/0.38~9.3600.0380.93154002030*1520*175072380Main

technical dataCylinder All the cylinders comprise upper plate,

diaphragms, and cylinder body etc. The diaphragms are clamped

between the cylinder cover and cylinder body. The cylinder cover

and cylinder body each has a concave recess hollowed out in

their contacting faces. The gas cylinder is formed between cylinder

cover concave recess and diaphragms. Both suction valve and

discharge valve are fitted on the upper plate. Among of them, the

discharge valve is located on the center of the upper plate. The

evenly located small oil holes are on the cylinder body to deliver

the oil pressure inside the oil cylinder to the bottom of

diaphragms (each diaphragm compressor's cylinder has three piece

diaphragm.) Pressure Regulating Valve The oil pressure of

oil cylinder is regulated by the tension of the valve spring.In

case the oil pressure is higher than the regulated value, turn the

regulating bolt counter-clockwise to loosen the spring tension, but

turn the regulating bolt clockwise to tighten the spring, when the

oil pressure is lo

Related products about High Purity Oil Free Diaphragm Compressor Helium Oxygen Hydrogen Gas Compressor

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup