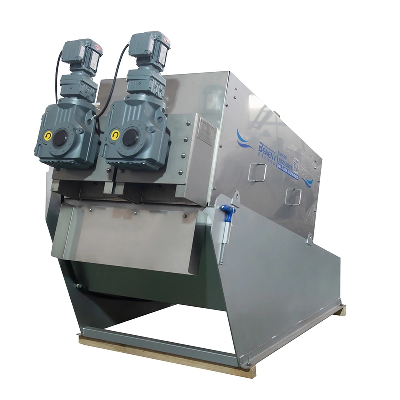

Product DescriptionMulti-disc screw press (Hereinafter referred to

as MDS) is a new generation of sludge dewatering machine, a screw

type sludge dewatering press having more advantages than belt

press, centrifuge, plate-and-frame filter press, etc. It features

clog-free, wide range of applications, power saving, fully

automatic control, low running cost, high resistance to oily

sludge, simple operation & maintenance, small footprint, etc. MDS

can be widely used in Municipal sewage, food, slaughtering

breeding, printing and dyeing, oil chemical industry, paper making,

leather, pharmaceutical and other industries of sludge

dewatering.Meanwhile, the unique self-cleaning mechanism and

stainless steel structure enables MDS to be ideal to dewater oily

sludge, which easily causes clogging and is difficult to treat with

other types of dewatering equipment. SpecificationsMain

ParametersCapacityDS-kg/hr180-300 DS-kg/hrSizemmL

3605×W1690×H1600PowerkW1.95MotorGearboxBrandSEW,

BAUER, SUMITOMO, NISSEIProtectionCertificates & IPUL,CE, Water

proof(IP65) CCCScrew ShaftTreatmentSUS316L, Tungsten carbide

coatingControl CabinetElectrical ComponentsBrandSchneider, Omron,

SiemensSolenoid ValveBrandUS, ASCOSpray SystemBrandJapan

Origin, H.IKEUCHIModel SelectionModelWAS Sludge& Chemical

Precipitated Sludge(Thin Sludge)Dissolved Air Flotation SludgeMixed

Raw SludgeAerobic Digested Sludge & Sewage SludgeSludge

Concentration (TS)0.2%1%2%5%3%MDS 051~0.4 kg-DS/hr(0.2 m³/hr)~0.6

kg-DS/hr(0.06 m³/hr)~2 kg-DS/hr(0.1 m³/hr)~4 kg-DS/hr(0.08 m³/hr)~5

kg-DS/hr(0.16 m³/hr)MDS 101~2 kg-DS/hr(1.0 m³/hr)~3 kg-DS/hr(0.3

m³/hr)~5 kg-DS/hr(0.25 m³/hr)~10 kg-DS/hr(0.2 m³/hr)~13

kg-DS/hr(0.43 m³/hr)MDS 131~4 kg-DS/hr(2.0 m³/hr)~6 kg-DS/hr(0.6

m³/hr)~10 kg-DS/hr(0.5 m³/hr)~20 kg-DS/hr(0.4 m³/hr)~26

kg-DS/hr(0.87 m³/hr)MDS 132~8 kg-DS/hr(4.0 m³/hr)~12 kg-DS/hr(1.2

m³/hr)~20 kg-DS/hr(1.0 m³/hr)~40 kg-DS/hr(0.8 m³/hr)~52

kg-DS/hr(1.73 m³/hr)MDS 202~16 kg-DS/hr(8.0 m³/hr)~24 kg-DS/hr(2.4

m³/hr)~40 kg-DS/hr(2.0 m³/hr)~80 kg-DS/hr(1.6 m³/hr)~104

kg-DS/hr(3.47 m³/hr)MDS 311~20 kg-DS/hr(10 m³/hr)~30 kg-DS/hr(3.0

m³/hr)~50 kg-DS/hr(2.5 m³/hr)~100 kg-DS/hr(2.0 m³/hr)~130

kg-DS/hr(4.33 m³/hr)MDS 312~40 kg-DS/hr(20 m³/hr)~60 kg-DS/hr(6.0

m³/hr)~100 kg-DS/hr(5.0 m³/hr)~200 kg-DS/hr(4.0 m³/hr)~260

kg-DS/hr(8.67 m³/hr)MDS 313~60 kg-DS/hr(30 m³/hr)~90 kg-DS/hr(9.0

m³/hr)~150 kg-DS/hr(7.5 m³/hr)~300 kg-DS/hr(6.0 m³/hr)~390

kg-DS/hr(13 m³/hr)MDS 412~80 kg-DS/hr(40 m³/hr)~120 kg-DS/hr(12

m³/hr)~200 kg-DS/hr(10 m³/hr)~400 kg-DS/hr(8.0 m³/hr)~520

kg-DS/hr(17.3 m³/hr)MDS 413~120 kg-DS/hr(60 m³/hr)~180 kg-DS/hr(18

m³/hr)~300 kg-DS/hr(15 m³/hr)~600 kg-DS/hr(12 m³/hr)~780

kg-DS/hr(26 m³/hr)Our Advantages(1) BENENV's sludge dewatering

machine is of unique dewatering structure with fixed and moving

rings. It has many advantages over other dewatering machines such

as plate and frame filter press, belt filter press and decanter

centrifuge, especially for power and rinsing water consumption and

labor cost saving. Below is a comparison table among them. (1) High

resistence to oily sludgeThe self-cleaning mechanism and stainless

steel structure enables MDS to be ideal to dewater oily sludge,

which easily cause clogging and is difficult to treat with other

types of dewatering equipment like belt filter press. (2) Clog-free

-- saving rinsing water -- saving costDue to the rotation of

helical axis, the moving rings begin detaching from the fixed rings

while continuously starting the self-cleaning process. As a result,

the ubiquitous clogging is avoided with the unique structure.

Therefore, it can handle oily sludge without any trouble while

separating the water from the sludge easily. In addition, there is

no need to add large quantity of rinsing water, thus MDS can saving

the cost. (3) Saving energy -- low power consumptionMDS works by

the machine's internal pressure and needs no large scale

integrations like rollers. It saves energy and water and has very

minimal noise because of low running speed (2-4 r/min). The average

unit power consumption is only 0.1-0.01 kwh/kg-Ds (1/8 of Belt

Press and 1/20 of Centrifuge). (4) Fully automatic control --

saving labor costThere are no easily blocked pieces such as belt

and filtration pore in MDS. Combining with the auto control system,

the machine runs very safely and simply and can be programmed

according to the requirement of the users. It can operate

automatically for 24 hours, unmanned. (5) Small footprint -- saving

the construction investment of dewatering roomWith the smart

design, MDS dewatering press can be installed in places where

placement would not be possible with other technologies. (6) No

thickeners -- saving the capital investment and costs on other

auxiliary equipmentMDS can treat sludge in aeration tank and

secondary sedimentation tank without setting sludge thickeners.

Therefore, this can decrease the total investment and costs on

mixers, air compressors, flushing pumps and other auxiliary

equipment. Dewater PrincipleThe initi

Related products about Multi-Disc Municipal Wastewater Treatment Equipment Screw Press Sludge Dewatering Equipment for Poultry Farm (MDS101)

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup