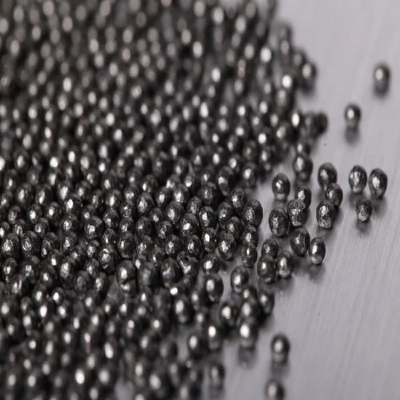

TAA brand metal blast abrasive low carbon steel shot ball

S390Product ParametersItemTechnique dataRemarks Chemical

Composition C 0.01%-0.20% Sulphur and Phosphorus are harmful

elements, should be reduced in order to decrease friability and

increase the fatigue life. Si 0.10%-0.35% Mn 0.35%-1.50% S ≤0.05 P

≤0.05 other alloy elements Adding Cr Mo Ni B Al Cu etc alloy

elements Adding alloy elements make it have the excellent property

of alloy steel Hardness HRC42-48 / 48-54 The proper hardness insure

the efficiency of surface treatment Microstructure Martensite and

Bainise duplex structure The duplex structure can ensure high

tenacity and high strength Product Feature:a. High

strengthen, high tenacity, long service life.b. Low breakage, low

dust, low pollution.c. Low wear of the equipment, long life of

accessory.d. Reduce dedusting system load, lengthen usage time of

dedusting equipment. Product ApplicationBlast

cleaning: Used for blast cleaning of casting, die-casting, forging;

sand removal of casting, steel plate, H type steel, steel

structure.Rust removal:Rust removal of casting, forging, steel

plate, H type steel, steel structure.Shot peening:Shot peening of

gear, heat treated parts.Shot blasting:Shot blasting of profile

steel, ship board, steel board, steel material, steel

structure.Pre-treatment:Pre-treatment of surface, steel board,

profile steel, steel structure before painting or

coating. Fatigue Life TestConsumption Contrast Figure of TAA

LCB steel shot, low-carbon steel shot and high-carbon steel

shot.(fatigue life test of normal grades at an impacting speed

ratio of 60.96m/s)Consumption contrast-Normal gradeThrough the

fatigue life test we can see that: the service life of TAA LCB

Steel Shot is 1.5 times longer than common low carbon steel

shot, 2 times longer than high carbon steel shot.Our

Advantages Company Profile ZIBO TAA METAL TECHNOLOGY CO.,

LTD is the leading manufacturer of blasting abrasives in China and

one of the top third suppliers all over the world. Founded in 1997,

TAA has been awarded as National Hi-Tech Enterprise, owning the

only metal abrasive engineering technology research centre in

China. Relying on the research centre, TAA has continuously

developed many high-performance products more suitable for

customers, including low carbon bainite steel shot, low carbon

bainite mixed abrasives, stainless steel cut wire shot, stainless

steel grit etc. Production processCertificationsWhy choose

us 1. TAA produce products following SAE standard, also

can produce customized abrasives catering for customers' various

requests, benefiting from our advanced production facility,

technology and quality control system.2. Our R & D technology

department has 40 people, who will provide you with consultation

and feedback. At the same time, we can also provide you with

absolutely free samples to meet your needs. We will try our best to

provide you with ideal services and products.3. The test

centre has perfect quality testing equipment, such as carbon-sulfur

analyzer, German QUANTRON Direct-Read Spectrograph,

metallographic micro-hardness tester, Screen tester, ERVIN

life tester and other quality control equipment. can check

composition, hardness, size distribution and service life etc,

ensuring products meet the international standards or the

requirements of customersTAA is committed to the provision of

high-end surface treatment equipment and solutions.It has finally

realized the surface treatment industry chain from metal abrasives

to surface treatment equipment and overall contracting services,

and as a "surface treatment integrated service provider", helping

users improve production efficiency and reduce operating costs by

providing high-quality products and overall services.

/* January 22, 2024 19:08:37

*/!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Taa Metal Blast Abrasive Low Carbon Steel Shot Ball S390

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup