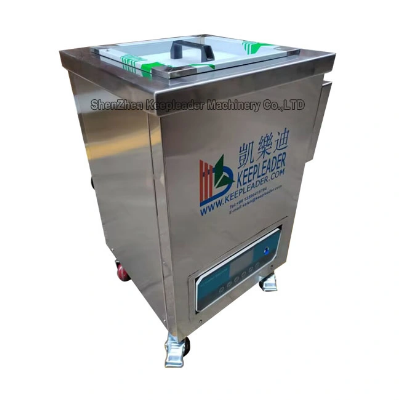

Test Sieves Cleaning Compact Ultrasonic Cleaner Test Sieves

Cleaning Compact Ultrasonic Cleaner takes design in speciality

to provide a safe and effective tricks for decontamination test

sieves, the compact and portable structure of standing-along

gratifying changeable working scenarios, that is operates on

110v,60hz or 550v,50hz cycle current, and requires little if any,

maintenance, the Test Sieves Cleaning Compact Ultrasonic

Cleaner produces ultrasonic vibrations in a cleaning fluid

bath, which cause contaminants to become dislodged from both the

sieve frame and media,vibrations up to 40000 per second are

transmitted to the cleaning solution, cleaning times ranges from

5~15 minutes, the unit will clean one 200mm diameter full height

test sieve qty: 4 in one basket at a timeProduct

Description Test Sieves Cleaning Compact Ultrasonic Cleaner01:

ApplicationTest Sieves Cleaning Compact Ultrasonic

Cleaner attains its speciality in its design of providing a

safe and effective reliability for decontamination test sieves,its

favorable characters embody compact structure,standing-along,

electric powered, no-toxic aqueous cleaning, easy operation and

little maintenance, ultrasonic cleaner produces ultrasonic

vibrations in a cleaning fluid bath, which cause contaminants to be

become dislodged from both the sieve frame and media, vibration up

to 40000 per second are transmitted to the cleaning solution with

in 5~15 minutes for test sieve of diameter: 200mm gratifying 4pcs

in a basket of one cycle,deposits and stuck particles reduce the

permeability of the metal sieves, which reduces re-productivity and

result accuracy, traditional cleaning cannot loose stuck particles,

with intensive ultrasonic cleaning, even the finest particles can

be cleaned off and the test sieves remain their original

accuracy,Test Sieves Cleaning Compact Ultrasonic

Cleaner creates microscopically small bubbles,when they

implode, gentle remove the dirt even from hard-to-reach recesses in

test sieves, after rinsing and drying, the cleaned screens function

reliable again, the service life is considerable extended by this

microscopic scrubbing treatment, and time and costs are saved02:

ParameterDescriptionTest Sieves Cleaning Compact Ultrasonic

CleanerModelKLE-1012Power SupplyPhase

Volt:220v/110v,50/60hzUltrasonic Power600wUltrasonic

Frequency40khzSieve Diameter200mmMax Qty of Sieve in a

Cycle4pcsCleaning TimeWithin 30 Minutes adjustableHeating

Power2000wInner size of cleaning chamber300*300*320Filling Volume

of Aqueous19LHeating Temperature40~60 Celsius DegreeDuration

Time10~15 MinutesMaterial of Oscillation ChamberStainless Steel

SUS304 and 316LSpectrum treatmentChrome CoatedQty of Vibrators12pcs

pf Each: 500w, 40khzAncillary FunctionDegas, Pulse Vibrating, and

Auto-sweep FrequencyUltrasonic GeneratorDigital Control, touch

screenNet Weight50kgsGross Weight66kgsPackaging

Size600*500*680kgs03: Cleaning ScheduleHow does Test Sieves

Cleaning Compact Ultrasonic Cleaner work?The unclean sieve is

first placed in an ultrasonic bath that is filled with in aqueous

cleaning liquid (made of water and high-quality ultrasonic cleaning

solution), when switched on, the the ultrasonic cleaner starts

cleaning ultrasonic waves that generate microscopic bubbles, these

collide vigorously with the soiled sieve surface placed within the

cleaning liquid, the process acts like a brush and is also called

cavitation which actually removes all the contaminants and fine

particles bonded to the sieve's surface without actually impacting

its made and design, the entire process involves is Eco-friendly

and hence is gentle as compared to the conventional test sieve

cleaning methods, likely manual brass cleaning, soak washing,

flushing and pressure cleaning04: Salient CharactersFull immersion

cleaning, 4 test sieve in one cleaning basket immersed into liquid

bathStanding-along, compact structure, convenient to moving at

working-sitesIndependent ultrasonic generator mounted at the bottom

power cabinetSpecial programs for cleaning of test sieve and sample

preparationSpecial efficient degas function to improve the

ultrasonic cavitationHigh performance 40khz ultrasonic

transducersUltrasonic tank made of cavitation-resistant stainless

steel Programmable logic control, touch screen,digital

control parameterTuning knob for setting continued and short-period

operation from 5~15minutes05: Use guidanceAs with any process

involving Test Sieves Cleaning Compact Ultrasonic Cleaner,

best results can be achieved by first removing loose contaminants,

when cleaning lab sieve do this by shaking or using a very soft

brush, after repeated cycles, cleaning efficiency will drop drop

off, this signal is that it is time to replace the cleaning

solution, drain the tank and follow local regulations regarding

solution disposal, take the time to clean the tank,particularly for

the bottom that is the location of ultrasonic spectrum, and using

citric saturated cloth to take rub cleaning can execute efficien

Related products about Test Sieves Cleaning Compact Ultrasonic Cleaner Machine for Laboratory Sieve_Sifter_Sieving Mesh Screen Ultrasound Particle Washing Bath of Ultrasonic Cleaning

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup