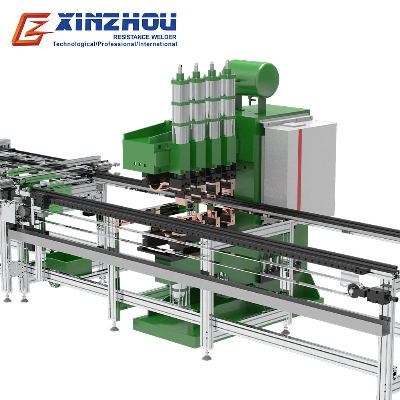

100kva steel wire mesh row welding soldering machine equipment

Product Description customized welder according to your

requirements series: DNW1/DNW2-P-L DNW1: Pneumatic AC row welder

with only upper cylinder DNW2: Pneumatic AC row welder with Upper

cylinder and lower cylinder P: Rated capacity L: Throat depth

(Length of arm) Product

ParametersNo.DNW-63-A-650/800DNW-80-A-650/800DNW-100-A-650/800DNW-150-A-650/800Rated

capacity63kva80kva100KVA150KVAvoltage380v380v380V380VRated

power50hz50hz50HZ50HZElectric current22KA24kA27KA30KALoad

duration20%20%20%20%Maximum pressure4800N4800N4800N4800NArm

length250mm250mm250MM250Arm depth

dimension650/800mm650/800mm650/800MM650/800MMCooling water

quantity4L/MIN4L/MIN4L/MM4L/MMweight330kg350KG370KG570KGOur

Advantages Feature and advantages-fast welding speed, high

efficiency. -adjustment is very easy -controller can store 15

welding schedules, to suit different specification workpieces.

-efficient weld, can weld multiple weld points with only one time.

-2 foot switches control 2 different welding schedules, to

control 2 PCS spec. Workpiece. - Universal application

- Upper arm of machine is insulated, no short circuit.

- Machine body of thick steel sheet, not easy to deformation,

good rigidity. - Microcomputer control, accuracy and steady - Water

cooling transformer: Use silicon sheets of 15000 gauss permeability

to pile up. There is cooling water in inside, using full copper

alloy core not aluminum, reducing impedance, improving the

utilization of power, 20% duty cycle to ensure the requirement of

long time welding, big output power. The useful lifetime is longer,

noise is smaller, structure is more compact and reasonable. -Fast

solenoid valve, making welding speed faster, thereby the

productivity is higher, therefore decreasing cost. - Cylinder

adopt high accurate, anti-friction hard material, which is

duralumin, without rust, lower friction, lower noise and loading is

faster, thereby reducing the weld spatter. - Lower loose weld rate,

less welding dregs. -It is easy to operate machine. Performance of

machine is more steady, can be used 24 hours, lifetime 15

years. Our Guarantee!!1. One year guarantee

time since machine leaves the factory2. Free component changes

under the normal condition3. Our engineers will be sent to help the

installation, debugging and training Company

ProfileCertifications Exhibition Packaging

& ShippingFAQQ1: What is the price of your machine?Answer: our

machines are customized for your requirements. If you want to get

the appropriate price, please provide us thefollowing information.*

The material and thickness of your product* The minimum and maximum

size of your product* The welding position of your products* The

automation level that you want to achieve* It would be better if

you can provide us the detailed product drawings so our engineer

can come out with the suitable technical proposal and price for

you.Q2: What is the warranty period of your machine?Answer: our

standard warranty period is one year after shipment. If you want to

extend the warranty period, there will be extra cost. Q3: What if

my machine damaged doing the warranty period?Answer: firstly, our

engineer will help you to diagnose the problem via online guidance.

if any parts damaged during the warranty period, we will send the

parts to you for replacement free of charge. If you can not fix he

problem by replacement of the new parts, we will send engineer to

your factory to help fixing the machine.Q4: What is the delivery

time of your machine?Answer: it depends on the complexity of your

machine. Most of our standard machine we got in stock, then we can

shape the machine with the seven days after receiving your payment.

If you need the Customized machine, normally it would take about

30-90 days to complete the machine.Q5: Can we send the sample to

you for welding test?Answer: yes. You can send us the samples for

welding test and we will send you the pictures and videos after the

testing. If you need, we can also send the samples back to your

country so you can check the welding quality by yourself before

ordering the machine.Q6: Can you provide us the machine drawings

and technical proposal?Answer: yes. After receiving your detailed

requirement and product drawings, our engineer will come out with

the suitableTechnical proposal with the basic machine concept

drawings to you. Be size after you placing the order we will send

you the more detailed design drawings of the machine to you for

confirmation. Only after you confirming the drawings then we will

start the manufacturing process.Q7: What's your payment

terms?Answer: we can accept the following payment terms: T/T, L/C,

Western UnionQ8: How can we install the machine?Answer: for some

simple machines we will provide you the english operation manual,

the operation video and also we will provide you the online

guidance and training to your engineer so you can set up the

machine easily. For some complicated machines, we

Related products about Stainless Steel Wire Mesh Cable Tray Welding Machine

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup